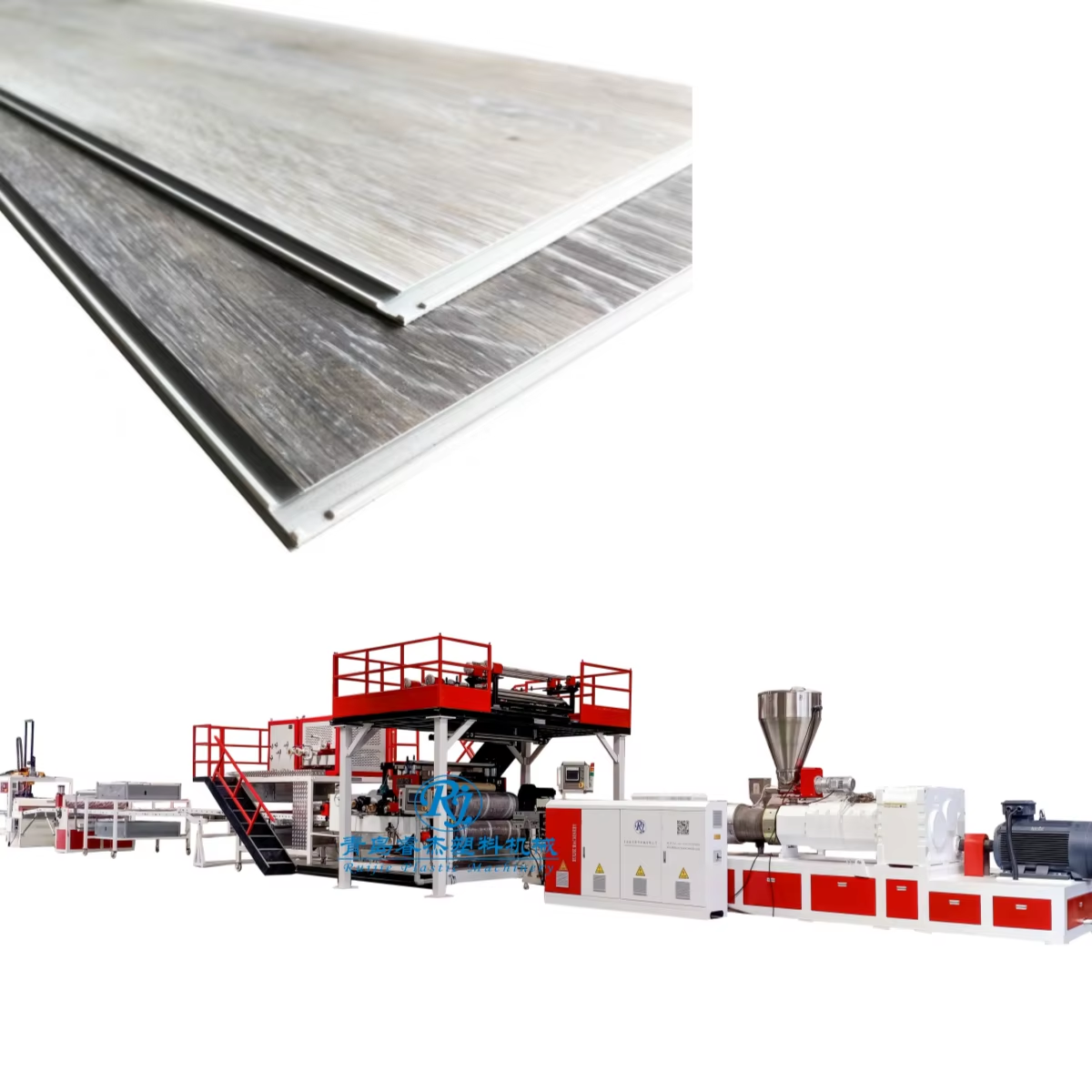

Resurs Səmərəliliyinin Bütünvləşdirilməsi LVT Döşəmə Maşını Dizayn

Bu günün LVT döşəmə avadanlıqları enerjini qənaət etmək və ətraf mühitə zərəri azaltmaq üçün hazırlanıb. Tanınmış istehsalçılar maşınlarda modul hissələrdən istifadə etməyə başlayıblar ki, bütün sahəni güc itkisinə yol verərək qızdırmaq əvəzinə, yalnız müəyyən bölgələri qızdarsınlar. Keçən il ScienceDirect tərəfindən aparılan tədqiqata görə, bu yanaşma köhnə modellərlə müqayisədə enerji israfını təxminən 18-22 faiz arasında azaldır. Maşınlar indi bütün otaqları qabaqcadan qızdırma ehtiyacını aradan qaldıran dəqiq infraqırmızı qabaqcadan qızdırma xüsusiyyətləri ilə gəlir, həmçinin temperaturu təxminən 1,5 dərəcə Selsi dəqiqliklə sabit saxlayan qapalı kontur temperatur idarəetmə sistemləri mövcuddur. Geniş şəkildə baxdıqda, bu təkmilləşdirmələr 2025-ci ilin Bərpa Olunan Enerji Tədqiqatı hesabatında tapılan nəticələrlə uyğundur. Hesabat daha yaxşı mühərrik invertor sistemlərinin sənaye miqyasında enerji istifadəsini 27 faizə qədər azalda biləcəyini göstərmişdi. Bank hesabı pozulmadan fəaliyyətlərini ekoloji cəhətdən təmizləmək istəyən şirkətlər üçün bu yeni maşınlar real irəliləyişdir.

LVT Döşəmə Maşınlarında Yüksək Səmərəli Matorlar və İstiliyin Geri Qaytarılması Sistemləri

İstehsalat zamanı maşınların sürətini azaldarkən təxminən 15-dən belə bəzi hallarda 20 faizə qədər kinetik enerjini geri qaytaran bərpaedici sürüş sistemi ilə gələn IE4 sinifli matorlara keçid etməklə bu enerjiyə əl çatdırmaq mümkündür. Bundan əlavə, ekstruziya proseslərindən çıxan istilik enerjisini toplayan istilik geri qaytarılma qurğuları da mövcuddur. Təkcə bu iki komponent, davamlı iş rejimində hər saat 8-dən 12 kilovata qədər enerji istehlakını azalda bilər. Əgər istehsalçılar bunları dəyişən tezlikli sürüş (VFD) ilə birləşdirsə, mövcud zavodların ümumiyyətlə istifadə etdiyi sistemlərlə müqayisədə matorların enerji istehlakını təxminən 30 faiz qədər azaltmaq mümkündür.

Aşağı Enerji İstehlakı üçün Ağıllı Avtomatlaşdırma və Proqnozlaşdırıcı Təmir

Həqiqi vaxtda işləyən sensorlar maşınların 32-dən çox müxtəlif tərəfini izləyir ki, bu da operatorlara maşınların boş dayanma vaxtı və ya istilik dövrlərini işə salma kimi parametrləri tənzimləməyə imkan verir. Avtomatlaşdırmanın səmərəliliyi ilə bağlı 2024-cü ilin son hesabatının ən son rəqəmləri olduqca təsirli bir nəticə göstərir: bu ağıllı texniki xidmət sistemindən istifadə edən zavodlar gözlənilmədən dayanmaları təxminən 41 faiz, enerji sıçramalarını isə demək olar ki, 30 faiz azaltmışdır. Bunu daha da yaxşılaşdıran şey maşın öyrənməsinin buradakı rolu o cür. Bu inkişaf etmiş modellər hər proses üçün lazım olan materialın dəqiq miqdarını müəyyənləşdirir və tullantıları əhəmiyyətli dərəcədə azaldır. İstehsal zamanı maşınlar artıq material çıxardığı üçün əvvəllər itirilən enerjidan 12-15 faiz əlavə qazanc əldə etməkdən danışırıq.

Tədqiqat nümunəsi: Alman zavodu İnfrasız prehidrola enerji istehlakını 38% azaltdı

Rinlandda yerləşən bir zavod LVT döşəmə avadanlığını, müxtəlif istilik mübadiləçiləri ilə birlikdə hər bir zona xüsusi olaraq uyğunlaşdırılmış infraqırmızı qızdırıcılar quraşdırmaqla yenilədi. Onlar qızdırma sahələrini məhsulların ehtiyaclarına tam uyğun gələcək şəkildə tənzimlədilər ki, bu da enerjinin itirilməsini azaltdı. Bundan əlavə, normalda itkiyə getmiş istiliyin təxminən 72 faizini geri qaytarmağı bacardılar. Bu dəyişikliklər onlara hər il enerji hesabları üzrə təxminən 240 min avro qənaət etmə imkanı yaratdı. Əslində ən təsirli olan budur ki, bütün bu proses ərzində istehsalat sürəti dəyişmədən qaldı. Beləliklə, şirkətlərin heç bir şəkildə istehsalı yavaşlatmadan elektrik xərclərində qənaət edə biləcəyini göstərir. Bu yanaşma çıxımı sabit saxlayarkən xərcləri azaltmağa çalışan böyük istehsalat müəssisələri üçün yaxşı işləyir.

Strategiya: Enerji israfını azaltmaq üçün maşın buraxılışının optimallaşdırılması

İstehsal cədvəllərini optimal maşın yükü ilə uyğunlaşdırmaq, hər ton məhsul üçün 22–31% daha çox enerji istehlak edən hissəvi partiyaların işlənməsini qarşısını alır. Məlumatlar göstərir ki, gündəlik ən azı səkkiz saat ərzində maksimum buraxılışın 85–90%-ni saxlamaq ümumi enerji səmərəliliyini 19% artırır və bu, qeyri-müntəzəm və ya parçalanmış iş dövrlərini üstələyir.

Material innovasiyası və dəqiq mühəndislik vasitəsilə vinil istehsalında tullantıların azaldılması

Ənənəvi LVT istehsalında xammal tullantılarının problemləri

Ənənəvi LVT istehsalı, səmərəsiz kəsmə və formalaşdırma səhvləri səbəbindən 7–12% material tullantısı yaradır (Green Building Council 2023). Xüsusiyyətlərə uyğun olmayan partiyalar optimallaşdırılmamış müəssisələrdə polad tullantıların 30%-ni təşkil edir və bu da inkişaf etmiş proses nəzarəti və dəqiq mühəndisliyin vacibliyini göstərir.

LVT tərkibində geri qaytarılmış komponentlər və istehlak öncəsi materiallar

Bu günlər bir çox aparıcı istehsalçı LVT istehsalına 25-dən 40 faizə qədər sənaye tullantıları olan PVC qarışıqları əlavə edir və məhsulun möhkəmliyində heç bir real azalma müşahidə etmir. Keçən il material innovasiyaları ilə bağlı dərc olunmuş bəzi tədqiqatlara görə, şirkətlər bu geri qaytarılmış komponentləri əlavə etməyə başlayanda, ISO 10582 keyfiyyət standartlarını hələ də təmin edərkən, yeni polimer materiallardan təxminən 18% daha az istifadə edirlər. Eyni zamanda emal texnikaları da olduqca inkişaf etmişdir və bu, yenidən işlənmiş materialların qarışdırılmasında daha yaxşı nəzarət imkanı yaratmışdır. Bu isə istehsalçıların xammal üçün ödədikləri məxaricin azalmasına kömək etmişdir. Grand View Research-in 2023-cü ildən olan tapıntılarına görə, bu, kvadrat metrə düşən xərclərdə təxminən iki dollar on səkkiz sent qənaət deməkdir.

Dəqiqlik Ekstrüzyonu və Tullantıları Minimuma Endirmək Üçün Maşın Kalibrlənməsi

Müasir LVT maşınları lazerlə idarə olunan kalıplar və süni intellektin qalınlığı nəzarət etməsi sayəsində ±0.15 mm ölçülü dəqiqliyə nail olur. Həqiqi vaxtda özlülüyü sensorları işləmə şəraitini işləmə zamanı tənzimləyir və əl ilə kalibrləməyə nisbətən standartdan kənar istehsalı 67% azaldır. Bağlı Dövri Yenidən İstifadə Sistemləri dərhal kənar qırıntıları yeni partiyalara qaytarın, optimallaşdırılmış qurğularda başlanğıc tullantılarını 41% azaldın.

Tədqiqat nümunəsi: İstehsalatın irəli səviyyə kalibrlənməsi sayəsində ABŞ müəssisəsinin tullantılarının miqdarı 45% azalıb

Orta Qərbdə yerləşən LVT istehsalçısı 22 ekstrüzyon xəttində maşın öyrənməsinə əsaslanan proqnozlaşdırıcı tədbirləri həyata keçirdi və planlaşdırılmamış dayanma ilə əlaqəli tullantıların illik səviyyəsini 8,2%-dən 4,5%-ə endirdi. Avtomatik qalınlıq kompensasiyası ilə birləşdirildikdə, 2,3 milyon dollara başa gələn yenidən avadanlandırma material xərclərinin və zərif torpağa tökülən tullantı haqqının azalması hesabına 14 ay ərzində investisiya qaytarıldı (Energetika Departamentinin Tədqiqat Nümunəsi, 2024).

Dövrün bağlanması: Karbonun azaldılması və davamlı həyat dövrünün idarə edilməsi

LVT döşəmə istehsalında qapalı dövr istehsal sistemi

Müasir LVT döşəmə maşınları istehsalat tullantılarının 98%-ni yenidən qatmaqla bağlı dövriyyəli istehsalı dəstəkləyir. Göstərildiyi kimi dövri iqtisadiyyat tədqiqatları , süni zərifin sonradan istehlakdan sonra 0,2 mm dəqiqliyi ilə müəyyənləşdirilməsini və ayrılmalarını təmin edən İA sistemi recycle qarışıqlarda kimyəvi uyğunlaşdırıcıların istifadəsinə ehtiyac yaratmır.

Tədqiqat nümunəsi: Avropa İstehsalçıları Recycle Girişləri İstifadəsi ilə 60% Aşağı CO₂ Əldə Etdi

Belçikalı bir istehsalçı LVT maşınlarını bağlı dövri material qidalandırıcıları ilə yenidən təchiz etdikdən sonra illik karbon emissiyalarını 3.200 ton qədər azaltdı. İnfrapıraqızıl spektroskopiyası keyfiyyət nəzarəti sistemi EN 649 aşınma qatı standartlarını keçərkən recycle maddənin 85%-dən istifadə imkanı yaradır.

İlkin Investisiyanın Uzunmüddətli Emissiya Qənaəti ilə Tarazlanması

Bağlı dövriyyəli yenidən təchizatlar kapital xərclərinin 18–25% artırılmasını tələb etsə də, operatorlar adətən aşağıdakı yollarla 34 ay ərzində xərcləri geri qaytarırlar:

- yeni PVC alışlarında 40% azalma

- material axınlarının sadələşdirilməsi hesabına 22% aşağı enerji xərcləri

- aB İTƏS çərçivəsində tonu üçün 12–18 avro karbon krediti yaratma

LVT döşəmələrin sökülməsi və istifadə ömrünün sonunda təkrar emalı üçün dizayn

Nəsil LVT maşınları həll edici maye olmadan yapışqanlardan istifadə edərək klik-bağlantılı lövhələr istehsal edir ki, bu da mexaniki aşındırma vasitəsilə materialların 94%-nin bərpasına imkan verir. İnkişafetmiş dizaynlara QR kodlu arxa təbəqələr daxildir ki, bunlar təkrar emal zamanı polimerlərin identifikasiyasını avtomatlaşdırır — bu, dünya miqyasında PVC-nin təkrar emalına olan tələbatın illik 7,8% artdığı şəraitdə əhəmiyyətli üstünlükdür (Circular Polymers Initiative 2024).

Davamlılığın təsdiqi: Həyat Dövrü Qiymətləndirməsi və Ekoloji Məhsul Bəyannamələri

LVT-nin davamlılığını artırmaqda Həyat Dövrü Qiymətləndirməsinin (HDQ) rolu

Həyat Dövrü Qiymətləndirmələri, qısaca HDQ-lar, LVT döşəmə maşınlarının başlanğıcdan sonuna qədər mühitə təsirinin nə qədər olduğunu sistemli şəkildə qiymətləndirməyin üsuludur. Biz burada xammalın çıxarılmasından tutmuş bu maşınların nəhayət artıq atılması ilə bağlı proseslərə qədər hər şeyi nəzərdə tuturuq. ISO 14040 standartlarında göstərilən təlimatlara əməl edərkən şirkətlər laminat səthlərin örtülməsi və ya ekstruderlərin işlədilməsi kimi proseslərdə ən böyük problemlərin harada olduğunu müəyyən edə bilirlər. Keçən il aparılan tədqiqatlar maraqlı bir faktı da ortaya qoydu: ekstrüzyon zamanı maşınların kalibrlənməsinin tənzimlənməsi istehsal olunan hər kvadrat metr üçün karbon emissiyasını təxminən 22% azaltdı. Belə nəticələr zavod sahiblərinə istehsala daha çox geri qaytarılmış materialların daxil edilməsi və ya daha yaxşı istilik pressləmə texnologiyasına investisiya qoymaq kimi hansı sahələrə diqqət yetirmələri barədə konkret istiqamət verir.

Məhsulun Ekoloji Bəyannamaları (MEB) Şəffaflıq Tələbinə Cavab Verir

Ekoloji Məhsul Bəyanatları Həyat Dövrü Qiymətləndirmə nəticələrini götürür və şirkətlərin davamlılıq iddialarını qiymətləndirərkən müqayisə edə biləcəyi real rəqəmlərə çevirir. 2022-ci ilin PVC Ekoprofilinin ən son rəqəmləri bu günki luks vinil plitə məhsulları haqqında maraqlı bir şey ortaya qoyur: onlar hələ də ənənəvi variantlar qədər yaxşı işləyir, lakin tez-tez təxminən 60% geri qaytarılmış material daxil edirlər. Keçən il Ponemon tədqiqatına görə, Amerikanın ticari döşəmə layihələri üçün tenderlər hazırlayan memarlarının beşdə dördü EPD-ləri tələb edir. Bu o deməkdir ki, istehsalçılar istehsal avadanlıqlarına xas ətraflı bəyanatlar verərək faktiki olaraq bazarда seçilirlər. Onlar suyun istehlakının azalması, quraşdırma zamanı yayılan uçucu üzvi birləşmələrin azalması və məhsulun bütün həyat dövrü ərzində karbon izinin azalması daxil olmaqla bir neçə sahədə konkret təkmilləşmələri göstərir.

Tədqiqat nümunəsi: Şimali Amerika Markası LCA vasitəsilə Körpədən Körpəyə Sertifikatı Qazanır

Son zamanlarda bir LVT istehsalçısı istehsalat prosesində aparılan əhəmiyyətli təkmilləşdirmələr nəticəsində Qızıl Cradle to Cradle sertifikatı qazandı. Şirkət ekstrüzyon avadanlıqlarını qapalı su sistemi daxil olmaqla yenilədi və materialların tərkibinə təxminən 34 faiz sənaye artı vinil əlavə etməyə başladı. Bu dəyişikliklər möhtəşəm nəticələr verdi: buraxılan tullantılar təxminən yarısına (təxminən 41%) endirildi, məhsulun həyat dövrü üzrə karbon qazı emissiyaları isə yalnız 18 ay ərzində təxminən 35% azaldıldı. Müstəqil auditorlar bu zavodda adətən tullantı hesab ediləcək olanın inanılmaz şəkildə 92%-nin yenidən istifadə oluna bilən xammala çevrildiyini müəyyən etdi. Bu, daha dövri istehsal modeli yaratmaq üçün gündəlik əməliyyatlara praktiki şəkildə tətbiq edildikdə, həyat dövrü qiymətləndirmə nəticələrinin nə qədər güclü ola biləcəyini göstərir.

SSS

LVT Döşəməsi Nədir?

LVT, Luks Vinil Plitka deməkdir. Bu, taxta və ya daş kimi təbii materialların görünüşünü təqlid edən, lakin möhkəmlik və təmizlənmənin asanlığını təmin edən döşəmə növüdür.

Modul dizayn enerji səmərəliliyinə necə kömək edir?

Modul dizayn maşınların bütün sahəni deyil, yalnız müəyyən zonaları qızdırmasına imkan verir, bu da əlavə enerji istifadəsini azaldır və səmərəliliyi artırır.

IE4 mühərrikləri nədir və niyə vacibdirlər?

IE4 mühərrikləri maşın işləyərkən itirilən kinetik enerjinin bir hissəsini geri qazanan yüksək səmərəli mühərriklərdir və bu, enerji istehlakının azalmasına töhfə verir.

Bağlı dövrü tullantılar sistemi nədir?

Bağlı dövrü tullantılar sistemi istehsal zamanı yaranan tullantıların yeni məhsul partiyaları üçün xammal kimi yenidən istifadə olunduğu, tullantıların və enerji istifadəsinin minimuma endirildiyi sistemdir.

Şirkətlər davamlılıq səylərini necə doğrula bilərlər?

Şirkətlər məhsullarının ekoloji təsirini və davamlılığını miqdarlaşdırmaq və açıqlamaq üçün Həyat Dövrü Qiymətləndirmələrindən (LCA) və Məhsulun Ekoloji Bəyanatlarından (EPD) istifadə edə bilərlər.

Mündəricat

- Resurs Səmərəliliyinin Bütünvləşdirilməsi LVT Döşəmə Maşını Dizayn

- LVT Döşəmə Maşınlarında Yüksək Səmərəli Matorlar və İstiliyin Geri Qaytarılması Sistemləri

- Aşağı Enerji İstehlakı üçün Ağıllı Avtomatlaşdırma və Proqnozlaşdırıcı Təmir

- Tədqiqat nümunəsi: Alman zavodu İnfrasız prehidrola enerji istehlakını 38% azaltdı

- Strategiya: Enerji israfını azaltmaq üçün maşın buraxılışının optimallaşdırılması

-

Material innovasiyası və dəqiq mühəndislik vasitəsilə vinil istehsalında tullantıların azaldılması

- Ənənəvi LVT istehsalında xammal tullantılarının problemləri

- LVT tərkibində geri qaytarılmış komponentlər və istehlak öncəsi materiallar

- Dəqiqlik Ekstrüzyonu və Tullantıları Minimuma Endirmək Üçün Maşın Kalibrlənməsi

- Tədqiqat nümunəsi: İstehsalatın irəli səviyyə kalibrlənməsi sayəsində ABŞ müəssisəsinin tullantılarının miqdarı 45% azalıb

- Dövrün bağlanması: Karbonun azaldılması və davamlı həyat dövrünün idarə edilməsi

- Davamlılığın təsdiqi: Həyat Dövrü Qiymətləndirməsi və Ekoloji Məhsul Bəyannamələri

- SSS