Increase Output with Automation in SPC Floor Machines

Automation revolutionizes SPC flooring production by integrating robotics and intelligent controls, delivering measurable efficiency gains while maintaining strict quality standards.

How automation streamlines SPC flooring production

Modern robotic systems take care of cutting materials, adding textures, and packaging products all with remarkable accuracy, which can cut down production time by nearly half in some cases. These machines come equipped with closed loop monitoring that cuts down on mistakes people might make and keeps measurements spot on within about 0.2mm. That kind of tight control saves money because it prevents waste from rejected materials. Looking at recent data from manufacturing efficiency reports around 2024 shows something interesting too. Factories using smart automation see roughly 30 percent fewer defects than those relying on hands-on work. Daily production numbers go up between 15 to 20 percent as well when these systems run nonstop and follow better organized workflows throughout the day.

Integration of AI and IoT in SPC floor machine operations

AI systems use prediction tools to spot when equipment might need fixing before it actually breaks down, which helps avoid those annoying unexpected stoppages. With IoT connections running throughout the production floor, things like temperature control, pressure levels, and how fast the lines are moving get coordinated between all the different machines. This lets operators tweak settings on the fly whenever materials change or behave differently than expected. The whole package cuts energy usage somewhere around 15-20 percent according to industry studies from last year, plus it keeps the curing process stable throughout batches. Smart factories have been reporting these kinds of improvements for quite some time now, as seen in recent Ponemon Institute research findings.

Case study: Achieving 40% higher output with automated SPC lines

One factory over in Europe went all in on automated SPC lines plus robotic material handling stuff, and they saw their output jump by around 40% just eight months after installation. The boost meant they could produce roughly 2,500 extra square meters worth of whatever product they make each day without needing any more workers. According to last year's Smart Manufacturing Impact Report, factories adopting similar automation approaches typically cut down their changeover time between production runs by about 70%. That happens because machines handle most of the tool switching automatically now. Plus there's been reports showing unit costs drop somewhere around 22% when companies invest in this kind of tech. Most manufacturers get their money back within about 14 months even though setting up such systems requires a pretty hefty upfront investment initially.

Achieve Superior Precision Using Advanced Calibration Systems

Laser-guided technology for unmatched SPC flooring accuracy

Modern SPC floor machines achieve micron-level precision using laser-guided calibration. Laser interferometers continuously monitor cutting and compression components with 0.001mm accuracy. Real-time feedback corrects alignment deviations during high-speed operation, eliminating dimensional inconsistencies in stone plastic composite tiles. This system automatically adjusts tooling paths mid-process, significantly reducing out-of-spec production.

Real-time thickness monitoring to reduce material waste

The sensors built into these systems check how dense and thick each tile is at around 200 spots every minute. If something's off by even 0.05mm, the machine automatically adjusts the pressure on all those hydraulics. At just one factory location, this kind of monitoring saves well over 200 tons of that special PVC and limestone mix each year. To put that number in perspective, it means about 15 thousand extra square meters of floor covering gets made without waste. The real benefit comes from stopping those tiles that don't get pressed properly in the first place.

Balancing high precision with maintenance efficiency in SPC machines

Calibration modules that can self diagnose problems rely on built in artificial intelligence to spot signs of wear long before accuracy starts dropping off. Instead of waiting for things to go wrong, maintenance gets scheduled during regular downtime periods whenever the system's own data shows something needs fixing. This cuts down those unexpected shutdowns by around two thirds compared to what most factories experience. Traditional systems need someone checking everything every week, but these smart modules keep machines running at their best most of the time. Factories report getting close to 95% uptime from this setup, all while eliminating the need for constant hands on inspections that eat into productivity hours.

Speed Up Installation with High-Performance SPC Floor Machine Systems

Innovations in rapid-lock mechanisms powered by SPC floor machines

The latest SPC floor machines come equipped with these clever click-lock systems that do away with the need for glue-down installations altogether. The machinery handles the tongue-and-groove alignment pretty accurately too, keeping things within about half a millimeter tolerance. Flooring pros report seeing around a 60% drop in installation mistakes since these systems became popular back in 2023. What really stands out though are those spring-loaded joints that make a distinct clicking sound when they lock properly. This means installers can keep working without constantly stopping to check if everything's secure. As an added bonus, all this tech saves roughly 45% on preparation time while still maintaining that crucial waterproof barrier which is so important for how well SPC floors actually perform over time.

Boosting installation rates from 500 to 1,200 sqm/day using advanced machinery

The latest SPC floor machines come equipped with conveyor systems that bring together cutting, aligning, and locking all in one smooth operation. Certified installation teams are hitting around 1,200 square meters per day on commercial jobs now, which is roughly twice what they managed before when the average was about 500 sqm/day according to Flooring Tech Journal from last year. What makes this possible? Well, there's the laser guidance system for planks that cuts down on measuring time by about four fifths. Plus we've got motorized feeds keeping everything moving at just the right speed, and automatic waste disposal that keeps the worksite from getting too messy. When all these tasks get handled automatically, workers can concentrate on actually laying out the flooring rather than dealing with equipment hassles. The result? Twice as much work gets done each day without needing any extra hands on deck.

Enhance Durability Through Optimized Composite Layering Technology

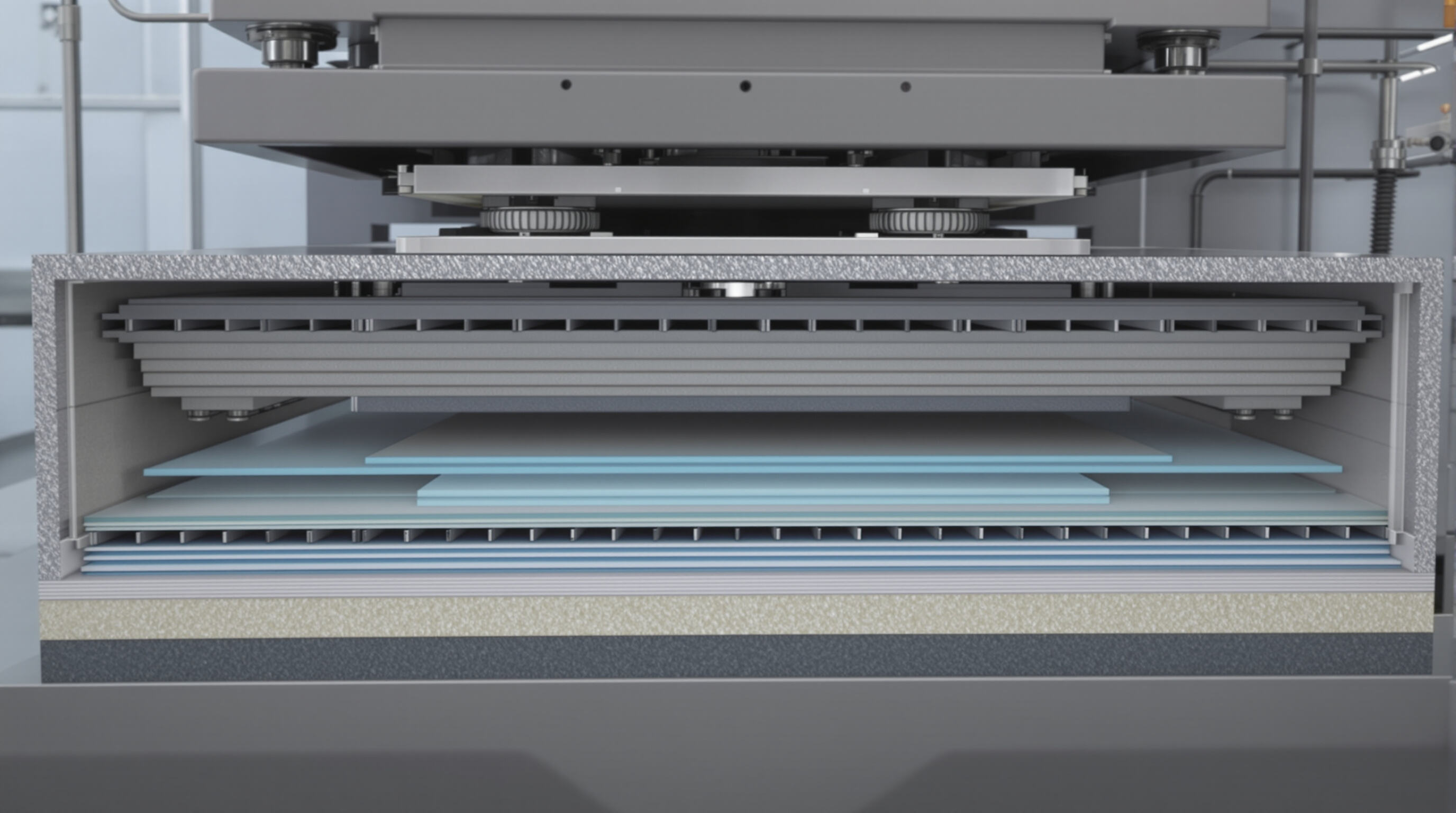

How SPC Floor Machines Improve Core Layer Compression and Stability

Today's SPC floor machines come equipped with advanced multi-stage compression tech that applies pretty serious pressure, sometimes hitting as high as 800 PSI, along with carefully controlled heat to bond those composite layers together. What these systems really do is spread out the materials evenly throughout the core structure, which gets rid of those pesky weak spots we often see when someone tries to make floors by hand. From what manufacturers have observed over time, the computer guided approach to making composites actually stops delamination issues before they start. Delamination remains one of the biggest headaches for anyone working with rigid core flooring products. The machines keep everything lined up properly layer after layer during production, so there's much less chance of getting those annoying separation problems down the road.

Data Insight: 30% Increase in Impact Resistance with Modern Machinery

Third-party testing confirms a significant durability improvement in machine-produced SPC flooring:

| Metric | Traditional Methods | Machine-Enhanced | Improvement |

|---|---|---|---|

| Impact Resistance | 1,200 N | 1,560 N | +30% |

| Layer Adhesion | 85% Uniformity | 99% Uniformity | +14 pts |

Automated quality control sensors adjust compression forces in real time—a capability absent in conventional lines—ensuring consistent performance and structural integrity.

Comparing Traditional vs. Machine-Enhanced SPC Flooring Performance

When it comes to hand layered SPC flooring, most options stop around 8 to 10 mm thick because anything thicker just won't stay stable. But those fancy machine made composite versions? They can go all the way up to 15 mm deep without losing their flexibility. Pretty impressive stuff actually. And speaking of improvements, newer calibration techniques cut down on wasted materials by roughly 22 percent when compared with old school manual methods. The International Flooring Standards Institute put these numbers together back in 2023. What's really changed though is how we make these floors now. Modern SPC machines can produce those hybrid core materials in one pass right? Mixing limestone, PVC, and various stabilizers together instead of going through three completely separate manufacturing steps like they used to. Saves time and money for sure.

Cut Labor Costs via Minimal Human Intervention in SPC Production

Reducing Labor Needs by Up to 60% Through Automated SPC Floor Machines

SPC floor machines with advanced tech now handle material movement, precise cutting jobs, and quality checks through built-in robotics systems. These machines cut down on manual work needs by roughly 60% in well set up production areas. The move toward automation is part of something bigger happening across industries right now. Global spending on smart factories hit over 330 billion dollars last year alone, showing just how important automation has become for keeping manufacturing costs under control. When people aren't doing the same repetitive tasks all day long anymore, companies tend to shift their workforce towards monitoring and technical support positions. This change boosts overall productivity without sacrificing product quality standards either.

Strategies for Workforce Reallocation in Smart SPC Manufacturing Facilities

As automation reduces frontline labor demands, facilities are transitioning staff to roles in machine supervision, process optimization, and data analysis. Cross-training programs equip workers to manage multiple automated systems, improving adaptability in high-tech environments.

Addressing the Debate: Job Displacement Versus Productivity Gains

While automation reduces manual positions, industry data reveals a 27% increase in technical roles since 2022, offsetting job losses in traditional functions. This shift highlights automation's dual benefit—lowering labor costs while creating higher-value opportunities in SPC floor machine maintenance and AI-driven quality assurance.

FAQ Section

What is SPC flooring?

SPC stands for Stone Plastic Composite, which is a type of rigid core flooring material known for its durability and ease of installation.

How does automation improve SPC floor machine operations?

Automation in SPC flooring machines integrates robotics and intelligent controls to enhance efficiency, maintain quality, reduce defects, and boost production rates.

Can automation affect job availability in factories?

While automation can reduce manual labor needs, it often leads to an increase in technical roles, enhancing productivity and creating higher-value opportunities.

What are the benefits of AI and IoT in SPC flooring production?

AI and IoT facilitate predictive maintenance, optimize machine settings in real-time, reduce energy consumption, and improve product consistency and quality.