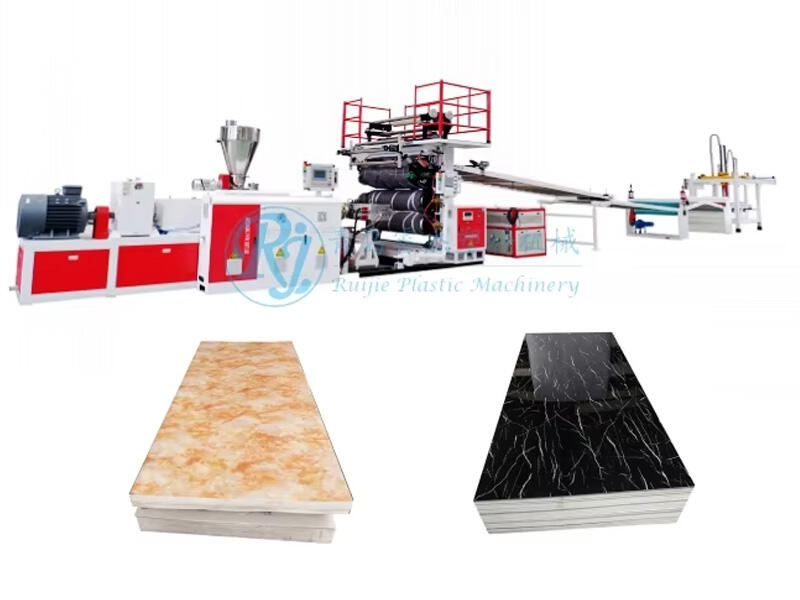

Kuptoni Si Funksionon një Makineri për bërjen e pllakave marmori Dhe Etapat Kryesore të Prodhimit

Kërkesa gjithnjë e rritur për fletë mermeri UV dhe PVC në ndërtimtarinë moderne dhe dizajnim interior

Profesionistët e ndërtimit dhe të dizajnit të brendshëm kanë nisur të kthehen drejt pllakave UV dhe PVC marmori sepse zgjasin më gjatë, duket shumë mirë në mjedise të ndryshme dhe kursen para në krahasim me alternativat nga guri i vërtetë. Sipas raporteve të fundit të industrisë nga Global Construction Materials në vitin 2023, po shohim rreth 17% rritje vjetore në këto siperfaqe dekorative. Njerëzit duan materiale më të lehtë që nuk kërkojnë mirëmbajtje të vazhdueshme, kështu që ky trend ka kuptim. Pllakat e prodhuara imitojnë pamjen e pasur të marmirit të vërtetë por janë më të forta edhe ndaj dëmeve nga uji, goditjeve dhe goditjeve fizike. Prandaj, shumë biznese i instalojnë ato në vende si tregtore, spitalet dhe madje edhe në shtëpi ku pamja është e rëndësishme por praktikabiliteti ka po aq rëndësi.

Parimet themelore: Përzierja, presimi dhe integrimi i tharjes me UV në makinën për bërjen e fletëve të marmirit

Procesi i prodhimit të fletëve të mermerit e kthen materiat bazike në sipërfaqe dekorative të bukura përmes tre hapave kryesorë. Hapi i parë përfshin përzierjen e rezinave PVC, mbushësve të karbonatit të kalciumit dhe stabilizatorëve të ndryshëm derisa të fitojmë një përzierje të qëndrueshme që imiton motive të gurit natyror. Më pas vjen faza e rrotullimit me presion të lartë ku rrotat specializuar formojnë këtë përzierje në fleta me trashësi dhe dendësi specifike. Në fund, ka fazën e ngurtësimit me UV që përdor dritë ultravjollcë të fortë për të ngurtësuar menjëherë shtresën e sipërfaqes. Kjo krijon ato siperfaqe të forta dhe të shkëlqeshme që thjesht nuk mund të arrihen me tharjen e zakonshme. Ajo që e bën këtë proces kaq efikas është mënyra se si këto faza lidhen pa probleme pa asnjë zbrazëti, duke rezultuar produktet që ruajnë formën e tyre, duken shumë mirë nëpër seritë prodhimi dhe mund të prodhohen me shpejtësi të çuditshme për prodhuesit.

Nga manualja te automatizimi: Zhvendosja e industrisë drejt linjash prodhimi të plotësisht integruara për fletë mermeri

Më parë, shumica e punës kryhej me dorë, por gjërat kanë ndryshuar në mënyrë të konsiderueshme që atëherë. Fabrikat e sotme funksionojnë me sisteme të integruara të prodhimit kompjuterik që merren me çdo gjë, nga ushqyerja e materialeve të para përmes proceseve të ekstrudimit dhe kalendrimit, deri tek përfundimi i produkteve me shumë pak nevojë për punonjës njerëzorë që qëndrojnë rreth dhe mbikëqesin makinat që kryejnë tërë punën e rëndë. Një raport i fundit i vitit 2024 tregon se sa shumë më të mira janë këto pajisje automatike krahasuar me metodat e vjetra. Prodhimi bëhet rreth 45 përqind më i shpejtë kur përdoren teknologjitë moderne, plus ka rreth 32% më pak material i humbur që shkon në harxhime. Në thelb të kësaj transformimi janë kontrollorët logjikë programues, të njohur zakonisht si PLC-të. Këto pajisje sigurojnë që çdo hap të funksionojë ngushëlluese së bashku. Ato ndihmojnë në ruajtjen e cilësisë së produktit edhe kur prodhohen mijëra artikuj njëkohësisht. Gjithashtu, kompanitë kursenojnë para në koston e funksionimit sepse nuk kanë më nevojë për aq shumë punonjës të specializuar. Kjo është shumë e rëndësishme tani, duke parë sa e vështirë është gjetja e personelit të kualifikuar që dëshiron të punojë në mjedise prodhimi.

Studim rasti: Përmirësimet në efikasitet me makinën automatike për prodhimin e fletëve të mermerit

Një sistem i ri automatik për prodhimin e fletëve të mermerit ka treguar përmirësime të mahnitshme si në shpejtësi ashtu edhe në ndikimin mjedisor në fabrikën tonë. Koha e prodhimit u ul me gati dy të tretat krahasuar me metodat manuale, ndërsa përdorimi i energjisë ra me pothuajse 40%. Arritëm gjithashtu të afrohemi me efikasitetin e përsosur të materialit – rreth 99,2% - falë monitorimit të vazhdueshëm të trashësisë së fletës dhe riciklimit të tërë mbeturinave përsëri në proces. Rezultati përfundimtar? Marzhat tona të fitimit rritën me 27% pas zbatimit të këtyre ndryshimeve. Sigurisht, kushtet fillestare ishin të larta, por duke parë numrat gjatë vitit të kaluar, investimi në automatizim rezulton shumë i fitueshëm në afat të gjatë.

Përputhja e funksionalitetit të makinës me shkallën tuaj të prodhimit dhe kërkesat e rrjedhës së punës

Zgjedhja e pajisjeve të duhura për prodhimin e fletëve të marmirit bazohet kryesisht në faktorë si shkalla e prodhimit, hapësira e disponueshme dhe aftësitë teknike ekzistuese. Për instalimet që prodhojnë nga 100 deri në 500 fleta çdo ditë, konfigurimet modulare zakonisht janë më të mirat, pasi mund të përballojnë dalje rreth 250 deri në 400 kilogramë në orë, duke lënë gjithashtu hapësirë për zgjerim kur kërkesa rritet. Kur kërkesat ditore kalojnë shenjën e 1000 fletëve, operacionet e mëdha zakonisht kanë nevojë për linja prodhimi të plota, të plotësuara me automatizim për manipulimin e materialeve dhe kontrolla të integruar të cilësisë, për të mbajtur procesin e shpejtë dhe për të zvogëluar kostot e punës manuale. Ka disa aspekte praktike që vlen të ketë parasysh gjatë montimit. Lartësia e tavaneve bëhet e rëndësishme gjatë instalimit të këtyre kullonave vertikale të ftohjes, furnizimi me energji duhet të jetë i mjaftueshëm për njësitë UV të ngurtësimit, dhe duhet të rezervohet hapësirë e mjaftueshme në dysheme jo vetëm për ruajtjen e materialeve të papërpunuara, por edhe për vendosjen e produkteve të përfunduara, në mënyrë që gjithçka të lëvizë pa pengesa nëpër instalim, pa u bllokuar në pika kritike.

Vlerësoni Fuqinë, Performancën dhe Efikasitetin Energjetik për ROI të Gjatë Kohës

Metrika kyçe të performancës: Kapaciteti i daljes dhe konsumi i energjisë së makinave për prodhimin e pllakave të mermerit

Kur shikoni një makinë për prodhimin e pllakave të mermerit, dy gjëra kryesore dallohen kur e vini në pyetje se sa efikase është ajo në realitet: sa output mund të prodhojë në orë (e matur në metër katrorë) dhe sa energji harxhon në kilovat. Le ta pranojmë, kostot e energjisë zakonisht përbëjnë rreth 40% të asaj që kompanitë harxhojnë për të eksploatuar këto makina nga dita në ditë. Kjo do të thotë se gjetja e pikës optimale midis arritjes së një prodhimi të mirë dhe mbajtjes së faturave të elektricitetit nën kontroll bëhet e rëndësishme për çdokënd që menaxhon operacionet. Në këtë moment, shumica e njerëzve në industrinë do ta konsiderojnë një standard të mirë dikund rreth 120 metër katrorë të prodhuar çdo orë, ndërkohë që përdor më pak se 45 kilovat energji. Makineria që arrin këtë nivel i lejon bizneseve të skalozojnë përpjekjet e tyre për prodhim pa parë që shpenzimet e tyre për energji po ngjiten jashtë proporcioni.

Modelet me fuqi të lartë kundrejt atyre me eficiencë energjetike: Balancimi i shpejtësisë dhe kushteve operative

Makinat me ratingje të larta fuqie midis 50 deri në 65 kilovatë ofrojnë me siguri rezultate të shpejta, megjithëse kushtojnë mjaft më shumë për t'u eksploatuar. Po flasim për rreth tetëmbëdhjetë mijë dollarë në vit nëse këto makina po funksionojnë pa pushim. Tani, krahasojini me alternativat energjetikisht eficiente me ratingje 30-45 kW. Këto modele ulin konsumin e energjisë ndërmjet njëzet e pesë deri në katërdhjetë për qind, pa iu dorëzuar shumë shpejtësisë, duke ruajtur rreth tetëdhjetë e pesë deri në nëntëdhjetë për qind të performancës së makinave më të mëdha. Për fabrikat që punojnë me disa turne gjatë ditës, kjo ndryshim shton shumë shpejt kur bëhet fjalë për para të vërteta të kursyera me kalimin e kohës. Kur vendoset se cili lloj është më i përshtatshëm për një biznes të caktuar, faktorë si çmimet lokale të elektricitetit kanë rëndësi të madhe, bashkë me volumin e produktit që duhet prodhuar dhe nëse konsideratat mjedisore luajnë rol në planifikimin e kompanisë.

Maxhimizimi i kthimit në investim përmes performancës së qëndrueshme të makinave

Pika kryesore është se qëndrueshmëria ka vërtet rëndësi për të fituar para me kalimin e kohës në biznesin e pllakave të mermerit. Kur prodhuesit investojnë në pajisje me eficiencë energjetike, ata përjetojnë përfitime që shkojnë më tej thjesht kursimit të kostove të elektricitetit. Këto pajisje zakonisht zgjasin më gjatë, gjë që do të thotë më pak dëmtime dhe më pak vështirësi me riparimet. Sipas asaj çfarë kemi parë në tërë industrinë, shumica e kompanive fillojnë të shohin rezultate brenda dy deri tre vjetësh kur merren parasysh edhe kursimet e energjisë edhe koha e humbur më e vogël për probleme mirëmbajtjeje. Disa teknologji të reja që vlen të merren parasysh përfshijnë sisteme që kapin energjinë e humbur gjatë funksionimit dhe veçori që kalojnë automatikisht në modalitet me fuqi të ulët kur nuk po presin gur. Këto përmirësime zakonisht ulin konsumin e energjisë rreth 25-30% në praktikë. Për pronarët e fabrikave që shikojnë përpara, kombinimi i zgjedhjeve të pajisjeve me nevojat e prodhimit dhe objektivat e menaxhimit të energjisë krijon një avantazh real. Ky qasje i ndihmon ata të mbeten përpara rritjeve të domosdoshme të çmimeve të energjisë dhe i mban ata në përputhje me rregulloret që vazhdojnë të evoluojnë në sektorin e materialeve ndërtimi.

Siguroni Saktësinë me Integrim të Avancuar CNC dhe Teknologji Gjymtimi

Si përmirëson teknologjia CNC saktësinë e gjymtimit në makina për prodhim pllakash mermeri

Teknologjia CNC ose Kontrolli Numerik i Kompjuterizuar mund të gjejë materiale me saktësi të jashtëzakonshme, nganjëherë aq të saktë sa plus ose minus 0.1 mm. Kjo praktikisht heq supozimet nga prodhimi, pasi çdo pjesë del pikërisht siç u vizatua në ekranin e kompjuterit. Mundësia e shumë boshteve hap me vërtetë dyert për krijimin e formave të ndërlikuara dhe dizajneve të hollësishme që do të ishin pothuajse të pamundura për t'u arritur me dorë. Kur bëhet fjalë për fabrikat prodhimi, këto makina ofrojnë produkte që duken njësoj batch pas batch-i. Ka shumë më pak nevojë për të rregulluar gabime dhe hedhur material copë timoni krahasuar me metodat tradicionale. Shumica e fabrikave raportojnë kursime me mijëra në vit thjesht nga ulja e materialeve të papërdorura.

Lëvizja mes shpejtësisë së prodhimit dhe saktësisë së gjymtimit

Sistemet moderne CNC kanë eliminuar plotësisht nevojën për të zgjedhur midis shpejtësisë dhe saktësisë. Këto makina vijnë me veçori si korrigjimi i gabimeve në kohë reale dhe procese automatike kalibrimesh që mbajnë precizitetin shumë të lartë, madje edhe kur funksionojnë me shpejtësi maksimale. Sistemet inteligjente të kontrollit përshtatin vazhdimisht cilësimet sipas atyre që zbulojnë, kështu që fabrikat mund të prodhojnë më shumë produkte pa u shqetësuar për dëmtimin e përfundimit të sipërfaqes. Kjo ka rëndësi të madhe në industri ku kompanitë duhet të jenë efikase, por gjithashtu të ofrojnë rezultate të përsosura për të mbetur para konkurrencës. Prodhuesit që investojnë në këto sisteme të avancuara zakonisht fitojnë kontrata sepse mund të respektojnë afate të ngushta duke ruajtur atë pamje cilësie premium që klientët presin.

Optimizimi i cilësisë së përpunimit të gurit për mjediset e prodhimit me volum të lartë

Kur punon në vëllime të mëdha, integrimi i teknologjisë CNC mban gjërat të sakta, edhe pasi janë prodhuar mijëra pjesë. Sistemet e reaksionit të mbyllur mbikëqyrin si nxehen mjetet me kalimin e kohës dhe ndryshimet në materiale, pastaj rregullohen vetë që të gjithçka të mbetet brenda afërsisht 0,1 mm të asaj që nevojitet. Çfarë do të thotë kjo? Më pak pjesë të gabuara që hidhen tej dhe prodhuesit mund të prodhojnë më shumë produkte pa kompromentuar cilësinë. Kjo është gjë shumë e rëndësishme kur kompanitë duhet të dorëzojnë sasi të mëdha të komponentëve identikë për projekte të mëdha ndërtimi ose klientë komercialë që presin që çdo artikull të plotësojë standarde të shtrenjta.

Krahasoni Teknikat e Përfundimit të Sipërfaqes: Veshja UV kundrejt Laminimit për Qëndrueshmëri dhe Estetikë

Pse pllakat prej marmere me veshje UV të gjërdheta dhe rezistente ndaj gërmitjeve po fitojnë preferencën e tregut

Fletët e mermerit me shtresa UV kanë bërë shumë të popullarizuar kohët e fundit sepse ofrojnë atë pamje të nxehtë që dëshirojnë njerëzit, si dhe mbrojtje më të mirë kundër gërvishtjeve. Kur flasim për shtresimin UV në krahasim me laminimin e zakonshëm, ekziston një ndryshim i madh. Metoda UV funksionon duke hedhur dritë ultravjollcë mbi një polimer të veçantë i cili ngurtësohet gati menjëherë, formojnë një shtresë të fortë të jashtme që zgjat më gjatë. Ajo që e dallon këtë proces është aftësia e tij për të theksuar ngjyrat më të gjalla, ndërkohë që zvogëlon konsiderueshmisht kohën e prodhimit në krahasim me teknikat e vjetra të laminimit. Për prodhuesit që merren me porosi të mëdha, ky faktor i shpejtësisë ka rëndësi të madhe, pasi kthimi më i shpejtë do të thotë potencial më i madh për fitim.

Si përmirëson teknologjia e shtresimit UV qëndrueshmërinë dhe cilësinë e përfundimit në prodhimin e fletëve të mermerit

Përshkrimet UV funksionojnë duke aplikuar një polimer të veçantë në formë lëngu që ngurtësohet shpejt kur ekspozohet ndaj dritës ultravjollcë. Kjo krijon një shtresë të gjithëpërfshirë dhe të rrjedhshme që reziston kundër grykimeve, reziston dëmtimit kimik dhe parandalon humbjen e ngjyrës nga ekspozimi ndaj diellit. Procesi në fakt bën sipërfaqet rreth 40 përqind më të forta sesa ajo që merret me laminatet tradicionale, plus ruajtja e një shkëlqimi uniform gjatë gjithë serive të prodhimit. Prodhuesit mund ta rregullojnë me kujdes sa e trashë aplikohet ky shtresë, gjë që ndihmon në ruajtjen e pamjes autentike të gurit, e cila është kaq e rëndësishme për produktet e kategorisë së lartë, duke ofruar në të njëjtën kohë mbrojtje të fortë kundër konsumit.

Informacione për kontrollin e cilësisë nga fabrikat mesatare për prodhimin e pllakave të marmirit me teknologji UV

Për prodhuesit e mesëm që punojnë me veshje UV, numrat flasin vetë për vete: rreth 99% cilësi e përsëritshme e përfundimit kur sensorët në kohë reale kapin këto ndryshime të vogla të trashësisë së veshjes deri në vetëm 0.1 mm. Procesi i ngurtësimit të menjëhershëm ndalon ato probleme të rrëfeshme që i njohim mirë nga metodat tradicionale - formimi i flluskave apo copëzimi i skajeve. Kjo do të thotë se fabrikat shohin uljen e normës së refuzimit rreth 30 përqind. Arkitektët e vlerësojnë këtë lloj besnikërie kur kanë nevojë për përfundime të përputhshme të shpërndara në pjesë të ndryshme të një vendi ndërtimi. Mendoni për ato hapësira komerciale të nivelit të lartë ku çdo panel duhet të duket saktësisht i njëjtë nga një mur në tjetrin.

Zgjedhja e një makineri për bërjen e pllakave marmori me module të avancuara laminimi dhe përpunimi të sipërfaqes

Për prodhimin e sotëm të fletave marmori, makineria ka nevojë të përballet me mbulesa UV dhe laminim nëse dëshiron të arrijë të gjitha segmentet e tregut. Kur pajisjet mund të kryejnë të dy llojet e përfundimeve, prodhuesit fitojnë fleksibilitet të vërtetë. Ata mund të prodhojnë fleta të laminuara me cilësi të lartë për hapësira komerciale të sofistikuara, ndërkohë që ofrojnë produkte me mbulesa UV të volitshme për porositë me volum të madh. Instalimet me performancë më të mirë zakonisht vijnë me koka aplikuese precize, sisteme automatike rregullimi trashësie dhe kontrolla të integruar cilësie gjatë procesit. Këto karakteristika sigurojnë që gjithçka të dalë me pamje të mirë, pavarësisht se klienti dëshiron një pamje premium apo thjesht diçka funksionale për instalime më të mëdha.

Rreshtoni Zgjedhjen e Makinerisë me Procesin tuaj të Prodhimit dhe Kërkesat e Fazës

Kuptimi i rolit të ekstrudimit PVC në prodhimin e fletave marmori dhe përputhshmëria e makinerisë

Procesi i ekstrudimit të PVC-së qëndron në zemrën e prodhimit të fletave të marmirit artificial, gjë që do të thotë se është shumë e rëndësishme që ky proces të funksionojë pa pengesa me pajisjet reale për bërjen e fletave të marmirit. Kur gjithçka përshtatet si duhet, materiali vazhdon të rrjedhë në mënyrë të qëndrueshme përmes sistemit pa u bllokuar kurrë. Kjo ndihmon në ruajtjen e një trashësie konstante në tërë secilën fletë, duke mbajtur një nivel të qendrueshëm dendësie midis serive të ndryshme. Nëse ky ekuilibër nuk respektohet, shkaktohen problemet më të ndryshme, nga sipërfaqet jo të barabarta deri te humbja e materialeve. Prandaj prodhuesit kushtojnë kaq shumë kohë sigurimit se linjat e tyre të ekstrudimit janë të përputhura saktë me çfarëdo që vjen më pas në zinxhirin e prodhimit. Një përshtatje e mirë mes këtyre fazave bën të mundur prodhimin e produkteve me cilësi në mënyrë të qëndrueshme, ditë pas dite.

Fletët UV të marmirit kundër gurit tradicional: Dallimet kryesore në proceset e prodhimit

Punimet tradicionale me gur përfshijnë të gjitha llojet e proceseve të pastra si heqja nga miniera, prerja dhe politura që prodhojnë sasi të mëdha të mbeturinave. Fletët e mermerit UV ndryshojnë sepse prodhohen duke përdorur teknika automatike përzierjeje, shtypjeje dhe ngurtësimi. E gjitha kjo sistem e ultet sasinë e materialeve të humbura dhe konsumin e energjisë falë kësaj metode të saktë për depozitimin e materialeve pikërisht aty ku nevojiten. Kur instalohen facilietet për këtë lloj prodhimi, planifikuesit duhet të fokusohen në zona si vendet për përzierjen kimike, linjat speciale të ngurtësimit me UV, si dhe pikët digjitale të kontrollit të cilësisë. Nuk ka nevojë për tërë ato pajisje të rënda prerëse apo sisteme komplekse për menaxhimin e pluhurit që janë standard në operacionet me gur natyror. Ka kuptim kur e mendojmë në këtë mënyrë, apo jo?

Planifikimi i facilieteteve: Hapësira, paraqitja dhe nevojat e kapacitetit për operacione efikase prodhimi fletësh mermeri

Planifikimi i mirë i pajisjeve fillon me vëzhgimin e mënyrës së përdorimit të hapësirës, ku lëvizin materiale dhe cilat janë nevojat për instalimet. Kur vendoset një ambient prodhimi, është e arsyeshme të vendoset makina për prodhimin e pllakave mermeri në një vend që e lehtëson manipulimin e materialeve pa zënë hapësirën e nevojshme për mirëmbajtjen e rregullt apo për zgjerime të mundshme në të ardhmen. Shumica e linjave prodhimi zënë nga 800 deri në 1200 katrorë të tokës, megjithatë duhet parashikuar edhe hapësirë shtesë për ruajtjen e materialeve të papërpunuara dhe të produktit përfundimtar. Mos harroni as për kërkesat e rëndësishme të instalimeve. Energjia elektrike tre fazore, sistemet e ajrit të ngjeshur dhe ventilimi i duhur nuk janë thjesht të dëshirueshme, por janë absolutisht të nevojshme nëse duam që mašinat të funksionojnë në mënyrë të qëndrueshme ditë pas dite dhe të ruajnë një cilësi konstante gjatë tërë kohëve.

Seksioni i FAQ

F1: Pse preferohen pllakat e mermerit UV dhe PVC në vend të gurit natyror?

A: Fletët marmore UV dhe PVC preferohen sepse janë më të qëndrueshme, me pamje tërheqëse në mjedise të ndryshme, ekonomike dhe kërkojnë mirëmbajtje më të vogël krahasuar me gurin natyror. Ata gjithashtu rezistojnë më mirë ndaj dëmtimit nga uji, gërvishtjes dhe goditjeve sesa guri natyror.

F2: Si ndikon automatizimi në prodhimin e fletëve marmore?

A: Automatizimi përmirëson efikasitetin e prodhimit duke e shpejtuar procesin me rreth 45%, duke zvogëluar mbeturinat e materialeve me afërsisht 32% dhe duke minimizuar nevojën për punë manuale, gjë që ul konsiderueshmisht koston operative.

F3: Cili është ndryshimi midis veshjes me UV dhe laminimit për fletët marmore?

A: Përshkrimi UV ofron një sipërfaqe të rëndë, rezistente ndaj gërvishtjes, që thekson ngjyrën dhe shpejtësinë e prodhimit krahasuar me laminimin. Ai gjithashtu krijon një shtresë të jashtme më të fortë që është më rezistente ndaj gërvishtjeve dhe dëmtimit nga ambienti.

F4: Cilat janë konsideratat për energjinë elektrike në makineritë për prodhimin e fletëve marmore?

A: Konsumi ideal i energjisë është më pak se 45 kilovat për të ruajtur efikasitetin pa kushte të larta energjetike. Makineritë me fuqi 30-45 kW e balancojnë mirë shpejtësinë dhe efektivitetin kosto-efektiv.

F5: Si e përfiton prodhimi i pllakave të mermerit nga teknologjia CNC?

A: Teknologjia CNC lejon prerje të saktë, cilësi të konstante të produktit dhe reduktim të humbjeve të materialeve, gjë që ndikon në uljen e kostove operative dhe rritjen e efikasitetit në mjediset e prodhimit me vëllime të larta.

Përmbajtja

-

Kuptoni Si Funksionon një Makineri për bërjen e pllakave marmori Dhe Etapat Kryesore të Prodhimit

- Kërkesa gjithnjë e rritur për fletë mermeri UV dhe PVC në ndërtimtarinë moderne dhe dizajnim interior

- Parimet themelore: Përzierja, presimi dhe integrimi i tharjes me UV në makinën për bërjen e fletëve të marmirit

- Nga manualja te automatizimi: Zhvendosja e industrisë drejt linjash prodhimi të plotësisht integruara për fletë mermeri

- Studim rasti: Përmirësimet në efikasitet me makinën automatike për prodhimin e fletëve të mermerit

- Përputhja e funksionalitetit të makinës me shkallën tuaj të prodhimit dhe kërkesat e rrjedhës së punës

-

Vlerësoni Fuqinë, Performancën dhe Efikasitetin Energjetik për ROI të Gjatë Kohës

- Metrika kyçe të performancës: Kapaciteti i daljes dhe konsumi i energjisë së makinave për prodhimin e pllakave të mermerit

- Modelet me fuqi të lartë kundrejt atyre me eficiencë energjetike: Balancimi i shpejtësisë dhe kushteve operative

- Maxhimizimi i kthimit në investim përmes performancës së qëndrueshme të makinave

- Siguroni Saktësinë me Integrim të Avancuar CNC dhe Teknologji Gjymtimi

-

Krahasoni Teknikat e Përfundimit të Sipërfaqes: Veshja UV kundrejt Laminimit për Qëndrueshmëri dhe Estetikë

- Pse pllakat prej marmere me veshje UV të gjërdheta dhe rezistente ndaj gërmitjeve po fitojnë preferencën e tregut

- Si përmirëson teknologjia e shtresimit UV qëndrueshmërinë dhe cilësinë e përfundimit në prodhimin e fletëve të mermerit

- Informacione për kontrollin e cilësisë nga fabrikat mesatare për prodhimin e pllakave të marmirit me teknologji UV

- Zgjedhja e një makineri për bërjen e pllakave marmori me module të avancuara laminimi dhe përpunimi të sipërfaqes

-

Rreshtoni Zgjedhjen e Makinerisë me Procesin tuaj të Prodhimit dhe Kërkesat e Fazës

- Kuptimi i rolit të ekstrudimit PVC në prodhimin e fletave marmori dhe përputhshmëria e makinerisë

- Fletët UV të marmirit kundër gurit tradicional: Dallimet kryesore në proceset e prodhimit

- Planifikimi i facilieteteve: Hapësira, paraqitja dhe nevojat e kapacitetit për operacione efikase prodhimi fletësh mermeri

- Seksioni i FAQ