Core Composition & Manufacturing Implications: PVC-Based LVT vs. Stone-Plastic Composite SPC

Understanding the core chemistry of Luxury Vinyl Tile (LVT) and Stone Plastic Composite (SPC) flooring reveals critical operational trade-offs. Each material's architecture—from polymer matrices to extrusion workflows—impacts production efficiency and end-product performance.

Polymer Matrix, Filler Chemistry, and Extrusion Dynamics

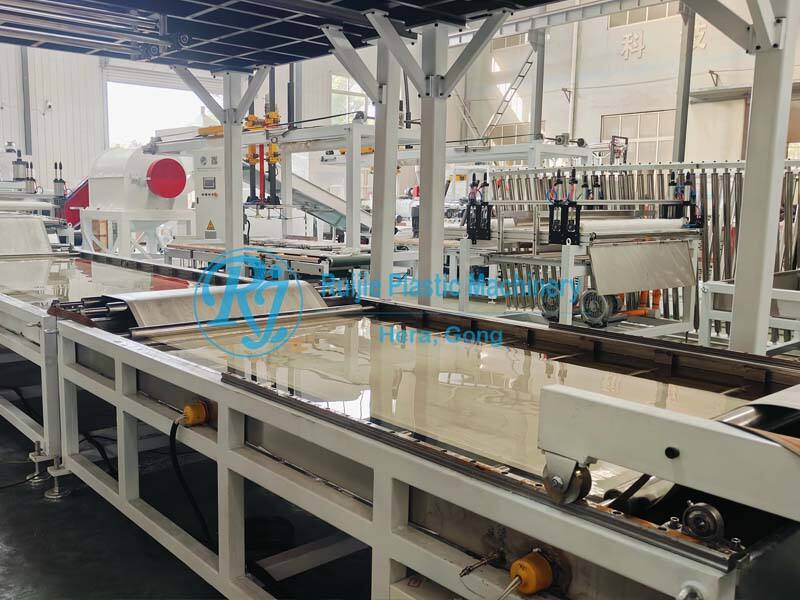

Luxury vinyl tile gets its flexibility from multiple layers of polyvinyl chloride, which makes it possible to install smoothly even when the floor underneath isn't perfectly flat. The core of this product is softer because it contains virgin PVC resins mixed with plasticizers, something that needs really careful calendering during the extrusion process. Stone plastic composite takes a different approach altogether. Its core is made up mostly of limestone powder about 60 to 70 percent calcium carbonate mixed with PVC and various stabilizers. Because of this dense formulation, manufacturers need to apply much greater pressure when pressing the material. Factory observations indicate that SPC lines run about 15 to 20 percent slower than standard LVT production lines. This difference in speed happens because of how thick and viscous the material becomes during processing, and it definitely impacts how much product can be manufactured within a given timeframe.

Thermal Stability, Line Speed Optimization, and Yield Management

Adding thermal compounds to SPC cores makes them hold their shape better when exposed to heat, which cuts down on shrinkage after production to around 0.05% or less compared with LVT's minimum of 0.1% according to ASTM standards. On the flip side though, LVT material is more flexible so it cools down quicker during manufacturing processes, cutting overall cycle time by about 22 percent as reported in last year's Materials Processing Journal. Most factories still go with SPC for jobs where temperatures run hot, but there's a catch. The material tends to chip at the edges quite easily when being handled, which actually means fewer usable pieces come out of each batch than with LVT. We're talking roughly 5 to 8 percentage points difference in yield rates between these two options.

Calcium Carbonate Loading Trade-offs: Dimensional Stability vs. Re-Grind Recyclability

The high mineral filler content in SPC products, sometimes reaching as much as 70% calcium carbonate, gives them excellent dimensional stability which matters a lot in places where there's lots of moisture around. Tests show these materials expand less than 0.01% after sitting in water for three days straight according to ASTM D471 standards. But there's a catch when it comes to recycling old material. When SPC waste gets loaded into grinders, it tends to jam things up pretty quickly and wears down machines at an alarming rate. Looking at reprocessed LVT instead tells a different story. With only about 30% filler content, it maintains roughly 92% of its original strength even after being processed again. From a sustainability standpoint, LVT just works better overall because it allows more flexibility during manufacturing processes while still holding up against changes in weather conditions and humidity levels.

Durability in High-Traffic Commercial Environments: LVT vs SPC Performance Benchmarks

Dent Resistance Across Thickness Tiers (2.5mm—6mm): ASTM F3369 Data Comparison

When it comes to resisting dents, SPC's stone plastic composite core beats regular LVT hands down across every thickness available on the market today, according to tests done under ASTM F3369 standards. Take a look at 2.5mm products for instance. These SPC boards can handle about 40 percent more point load pressure than similar LVT options before showing any real damage signs, averaging around 1,200 psi. Things get even better when we talk about thicker materials. At 6mm thickness levels, SPC floors stand up against impacts reaching up to 1,800 psi. That makes them ideal choices for places where there's constant heavy traffic from carts and equipment, think warehouses or hospital corridors. Another big plus is how the solid core construction blocks those annoying floor irregularities from showing through on top, unlike standard LVT which needs absolutely flat surfaces underneath to work properly.

| Thickness | Material | ASTM F3369 Dent Resistance | Recommended Use Case |

|---|---|---|---|

| 2.5mm | SPC | 1,200 psi | Boutique retail, offices |

| 2.5mm | LVT | 850 psi | Low-traffic commercial spaces |

| 6mm | SPC | 1,800 psi | Airports, healthcare facilities |

| 6mm | LVT | 1,100 psi | Hospitality corridors |

Field Failure Analysis: Retail and Healthcare Installations (2022—2024)

Recent field studies reveal distinct failure patterns between LVT and SPC in demanding commercial settings. In retail environments with high cart traffic:

- SPC installations showed <3% dent-related failures after 24 months—mostly confined to entryways

-

LVT installations exhibited 18% edge delamination and 12% permanent indentation near checkout lanes

Healthcare facilities documented 22% moisture-related LVT failures in sterile processing areas versus just 4% for SPC—attributed to SPC’s near-zero water absorption. Wheelchair-intensive zones saw 30% fewer replacement incidents with 5mm+ SPC flooring, per 2023 healthcare facility maintenance reports.

Moisture Resilience & Subfloor Compatibility: Critical Considerations for LVT vs SPC Flooring

Immersion Resistance (ASTM D471) vs. Real-World Moisture Vapor Transmission Thresholds

ASTM D471 tests show that SPC has a completely waterproof construction, but real world issues with moisture vapor transmission present bigger problems when installing LVT floors. The solid stone plastic core of SPC acts as a barrier against moisture coming up from below, which protects the floor's structure particularly well in areas like basements or concrete slabs where MVT levels can go over 5 pounds per thousand square feet per day. On the other hand, the flexible layers of vinyl in LVT might let vapor through at the seams if exposed for long periods. Research published in 2023 revealed something interesting about how these materials react to water. After being submerged for three days straight, SPC only expanded by less than 0.05%, while LVT expanded around 0.3% at those same seams. This makes SPC especially valuable for places such as restaurants or hospitals where keeping adhesives intact is critical. Contractors report seeing about 34% fewer callback jobs because of moisture issues, based on recent industry audits.

B2B Installation Economics: How LVT vs SPC Flooring Impacts Labor, Tooling, and Project Scalability

What materials get chosen really affects how much money gets spent on installation and whether a flooring project can scale up effectively. The rigid core in SPC makes those floating click lock systems possible, which cuts down labor time somewhere around 15 to 20 percent compared to traditional glued down LVT floors according to industry standards. This kind of efficiency matters a lot when doing big installations fast, especially important for places like stores needing renovations during off hours or hospitals working within short windows between shifts. Sure, LVT tends to be cheaper per square foot at about $2 to $4.50 while SPC runs closer to $2.50 to $5. But when companies buy in volume, they find that the extra cost gets made up through all those saved man hours and simpler tools needed for installation. Another thing worth mentioning is how SPC handles small bumps and dips in existing floors better than LVT does. With LVT, contractors have to spend extra time making everything perfectly level before starting work. When businesses need to replace flooring across multiple locations quickly without losing too much income from closed facilities, many are finding that despite higher upfront costs, SPC actually ends up being more cost effective overall in the long run.

FAQs

- What is the core difference between LVT and SPC flooring?

- LVT (Luxury Vinyl Tile) primarily consists of polyvinyl chloride, whereas SPC (Stone Plastic Composite) includes limestone powder mixed with PVC. This makes SPC more rigid and durable than LVT.

- Why is SPC slower to produce compared to LVT?

- The dense formulation of SPC requires higher pressure during manufacture, which slows down production lines by 15-20% compared to LVT.

- Which flooring is more resistant to moisture?

- SPC is generally more resistant to moisture due to its solid core, making it ideal for wet environments.

- Are there recyclability concerns with SPC?

- Yes, SPC's high mineral content can cause issues in grinders and lead to faster wear of machinery. LVT, with lower filler content, can maintain more of its original strength after being reprocessed.

Table of Contents

- Core Composition & Manufacturing Implications: PVC-Based LVT vs. Stone-Plastic Composite SPC

- Durability in High-Traffic Commercial Environments: LVT vs SPC Performance Benchmarks

- Moisture Resilience & Subfloor Compatibility: Critical Considerations for LVT vs SPC Flooring

- B2B Installation Economics: How LVT vs SPC Flooring Impacts Labor, Tooling, and Project Scalability

- FAQs