Core Material Science: How SPC and LVT Composition Dictates Production Requirements

The fundamental differences in SPC (Stone Plastic Composite) and LVT (Luxury Vinyl Tile) floor production stem from their core compositions—which directly dictate manufacturing processes, equipment selection, and end-use performance.

SPC Core: Calcium Carbonate–PVC Blend for Dimensional Stability and Pressing Compatibility

SPC flooring has what's called a dense, rigid core made mostly from ground limestone mixed with PVC resin. The exact mix can vary between around 60 to 80 percent calcium carbonate. What makes this material so special is how stable it stays when temperatures change. We're talking about expansion or contraction rates of just plus or minus 0.05 percent even when there's a temperature swing of 30 degrees Celsius. That kind of stability makes SPC floors work really well in tricky spots like sunrooms where heat builds up during the day, or commercial kitchens where temperatures fluctuate constantly throughout service hours. Because the material is so dense and not very elastic, manufacturers can press these floors under high pressure ranging from 80 to 100 MPa. This allows for quick cooling without any warping issues that plague other materials. On factory floors, they need to keep everything calibrated precisely so each batch comes out with that standard 4 to 7 mm thickness everyone expects.

LVT Core: Homogeneous PVC Compound Optimized for Calendering and Embossing Precision

LVT features a flexible PVC plastisol core that doesn't contain any mineral fillers, focusing more on being easy to work with than being rigid. This particular makeup works well during the multi stage calendering process, which involves heated rollers pressing the material down into sheets that are typically around 2 to 3 mm thick. What makes LVT special is how the PVC maintains just the right consistency for embossing at the micron level, with tolerances as tight as plus or minus 0.1 mm. This precision lets manufacturers create really convincing wood grain effects and stone like textures. But there's a catch worth mentioning here. Because PVC reacts so strongly to heat changes, production facilities need to use specially designed cooling tunnels that operate with temperature differences between 20 and 30 degrees Celsius. These slower cooling processes help avoid problems like layers coming apart, shrinking issues, or weird surface deformations that would ruin the product quality.

| Property | SPC Core | LVT Core |

|---|---|---|

| Primary Material | Limestone-PVC Composite | Homogeneous PVC Plastisol |

| Thermal Stability | ±0.05% dimensional change (±30°C) | ±0.12% change (±20°C) |

| Processing Speed | 25–40 m/min (compression) | 15–25 m/min (calendering) |

Manufacturing Process Architecture: Pressing vs. Calendering in SPC and LVT Floor Production

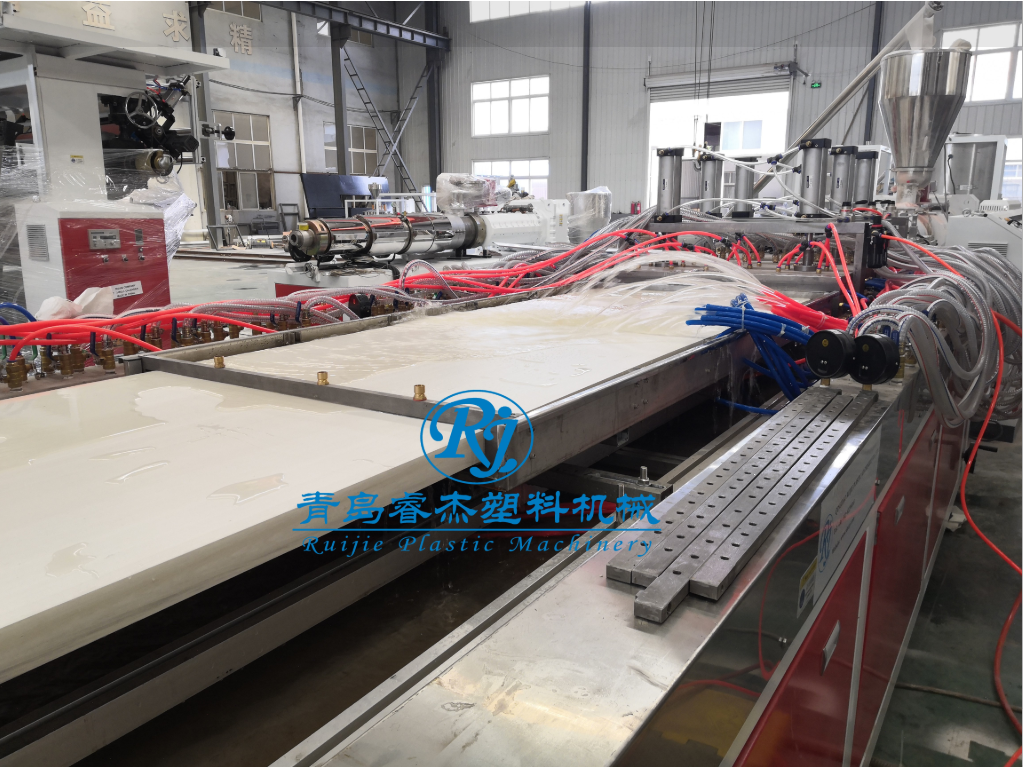

SPC Production Line: High-Pressure Compression, Rapid Cooling, and Integrated Click Machining

The SPC manufacturing process relies heavily on temperatures between 175 and 190 degrees Celsius along with significant pressure to completely bind together the mixture of limestone and PVC. When done right, this method prevents those pesky layer separations we often see in other materials and gives the product real structural strength. After pressing, quick cooling is applied so the material sets fast, which helps keep everything nice and flat without warping at the edges. Next comes the CNC machining stage where machines cut out those interlocking profiles right there on the production line. The tolerances here are pretty tight too, around plus or minus 0.2 millimeters. All these automated steps mean factories need far fewer workers than they used to for finishing work, probably cutting down on labor costs somewhere around 60 percent when compared to older methods that required lots of handwork.

LVT Production Line: Multi-Stage Calendering, Registration-Sensitive Embossing, and UV-Cured Wear Layer Integration

The process for making LVT starts with something called multi-roll calendering which creates sheets that stay stable in size and shape while maintaining an extremely uniform quality throughout. What comes next is really critical though - the embossing stage where textures need to match up perfectly with the printed designs. We're talking about alignment down to the micron level here. Even a tiny mistake of just 0.1 mm can mean throwing away an entire batch of product. After all that, they apply a special wear layer that gets cured using UV light. This forms a surface that resists scratches and scuffs pretty well. But there's a catch. To get everything right during this final step, manufacturers have to keep a close eye on several factors at once including humidity levels in the air, temperature settings for rollers, and how intense the UV light actually is. Get any of these wrong and problems like hazing effects or what looks like orange peel texture might show up, not to mention when the material doesn't cure properly at all.

Performance & Compliance Drivers: How Market Demands Shape SPC and LVT Floor Production Decisions

Commercial Sector Priorities: Healthcare and Education Demand SPC’s Rigidity, Acoustic Dampening, and Low-Maintenance Output

More healthcare centers and schools are turning to SPC flooring because of how well it holds up under tough conditions. The dense mineral core gives it real strength to handle all those rolling carts and medical equipment, plus it takes a beating when things get dropped on it without dents forming as easily as regular vinyl would. We're talking around 70% fewer dents in most cases. For noise control, commercial grade SPC comes with built-in acoustic padding that cuts down impact sounds by about 19 decibels. That meets pretty strict building standards too, including ASTM E492 and ISO 140-6 requirements. And let's not forget the antimicrobial surface layer. These floors actually keep working against germs even after being hit with harsh hospital cleaners again and again. Over time, this means they last longer than wood or laminate options while saving roughly 30% in maintenance costs across their lifespan.

Sustainability Regulations: VOC Limits, PVC Phase-Out Timelines, and Recyclate Integration Challenges Across Both Lines

Regulatory pressures around the world are changing how SPC and LVT products get made. Take the EU's Circular Economy plan for instance. By 2030 they want at least 60% recycled material in building stuff, which means factories have to work harder to mix in post-industrial recyclate without messing up the dimensions or look of their products. Then there's California with its new VOC rules (no more than 50 micrograms per cubic meter). This has forced companies to rethink their formulas for glues, wear layers, and those plastic additives. And over in Scandinavia plus Canada, laws banning PVC are speeding up research into safer alternatives like phthalate-free options and plant-based plasticizers. Getting recyclate integrated properly isn't easy though. Contaminants can really mess with the extrusion process for SPC, while inconsistent colors plague LVT aesthetics. Some top manufacturers are tackling this head on with AI systems that sort materials visually and monitor rheology during production lines. These technologies allow them to include around 40% certified recyclate content these days, hitting green goals while still keeping product quality intact and meeting all the necessary regulations.

FAQ

What materials are SPC and LVT floors made of?

SPC floors consist of a limestone-PVC composite, while LVT floors are made of homogeneous PVC plastisol.

Why does the core composition affect the manufacturing process for SPC and LVT?

The core composition dictates thermal stability and necessary production methods, such as pressing or calendering, affecting both handling and cooling processes.

What makes SPC floors suitable for commercial environments like healthcare and education?

SPC floors have a dense, rigid core that provides durability against heavy equipment and rolling carts. They also include acoustic padding for noise control, and have an antimicrobial surface layer ideal for sanitation needs.

How are sustainability regulations influencing SPC and LVT production?

Regulations require increased use of recycled materials and limit VOC emissions. This pushes manufacturers to adjust formulations and production methods to adhere to these standards while maintaining quality.