All Categories

All Small Categories

HDPE Single Wall Corrugated Pipe Extruder PVC Conduit Pipe Machine Production Line

- Description

HDPE Single Wall Corrugated Pipe Extruder PVC Conduit Pipe Machine Production Line

Production Description

High speed corrugator:

Close type corrugater and vacuum for forming.

Forming mould is moving in a tunnel.

Forming tunnel os clod by water.

Forming mould is made of hard alloy steel and anti-corrosion and abrasion.

No any connection between forming mould, then reduce time to change.

Provide single wall corrugation dead die.

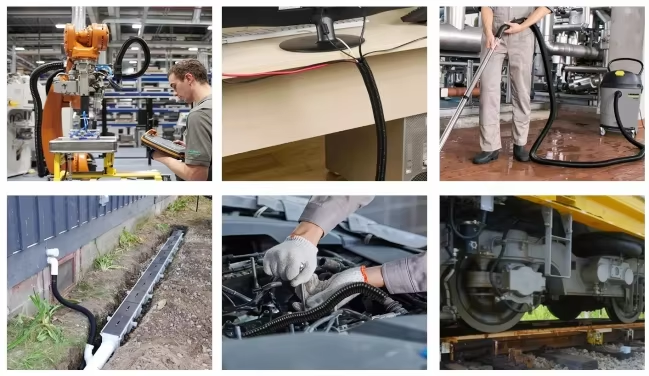

Use: HDPE Single Wall Corrugated Pipe Extruder PVC Conduit Pipe Machine Production Line can produce pipe with heating-proof , corrosion-proof, friction-proof and high strength . And the pipe will be used in electricity/pneumatic wire conduit , Auto wire conduit , protection conduit , machine tools , electric locomative, projections installation , lights, automatic tools and other fields . It is a big market demand .

Characteristics and advantages:

1. Special structure design of screw and dies and convenience in changing mould blocks solve the problem of easy-worn of screw and barral ,as well as the difficulty in forming of plastic resin .

2. Corrugator adopts closed water cooling structure ,closed forming blocks chain ,and special design of rail, which will make all blocks matching correctly ,running stablely . You even couldn’t see the connecting line on the surface of pipe . Cooling water is cycling inside the corrugator ,it will make the cooling speed fast, so the production speed of pipe will be raised highly .

Meanwhile ,the corrugator adopts building blocks design , we can use same basis structure but different forming length of corrugator . The longer forming length of corrugator , the more output of pipe . We can make different forming length corrugator according to different cusotmers’ needs.

Technical Parameter

Model number |

SJ32 |

SJ45 |

SJ55 |

SJ63 |

Pipe diameter |

8-12mm |

16-32mm |

16-50mm |

16-63mm |

Max output |

15-25kg/h |

30-50kg/h |

40-60kg/h |

50-80kg/m |

Max Production rate |

9m/min |

12m/min |

13m/min |

14m/min |

Extruder model |

SJ35/30 |

SJ45/30 |

SJ55/30 |

SJ65/30 |

Installed power |

18kw |

30kw |

50kw |

60kw |

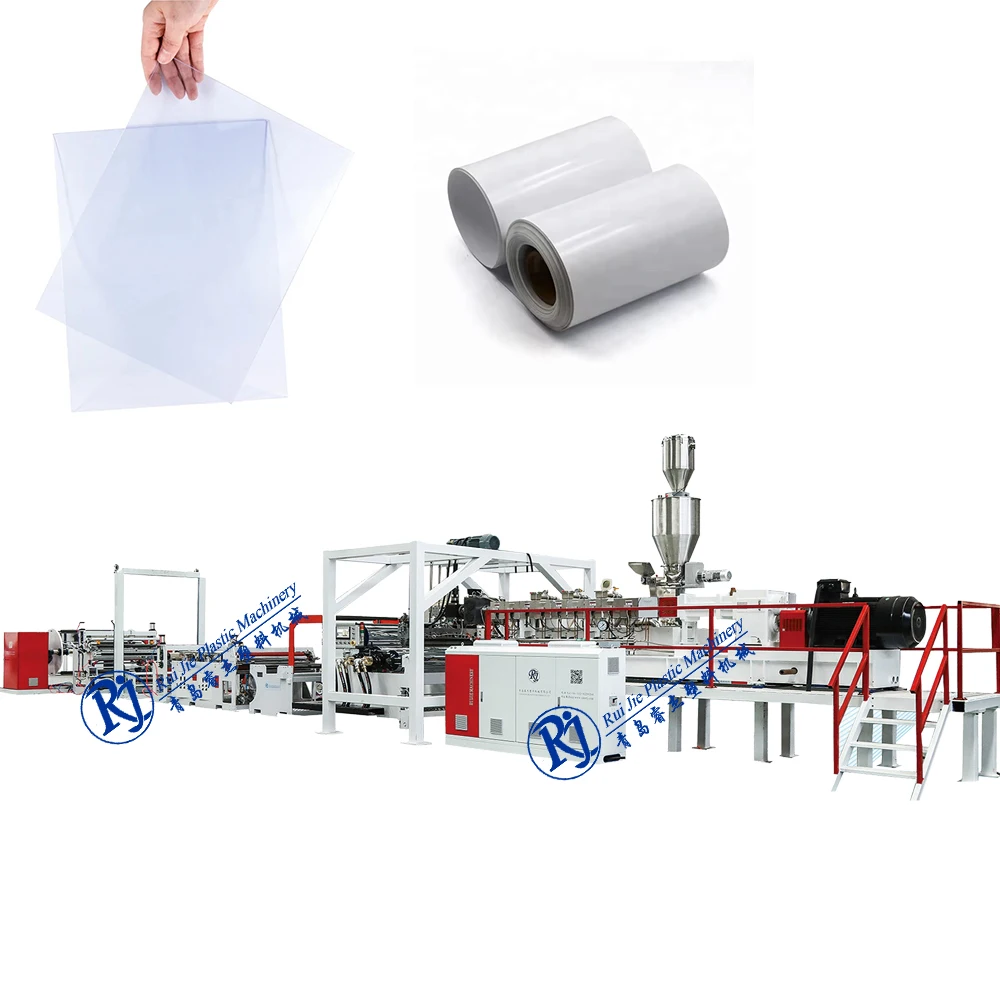

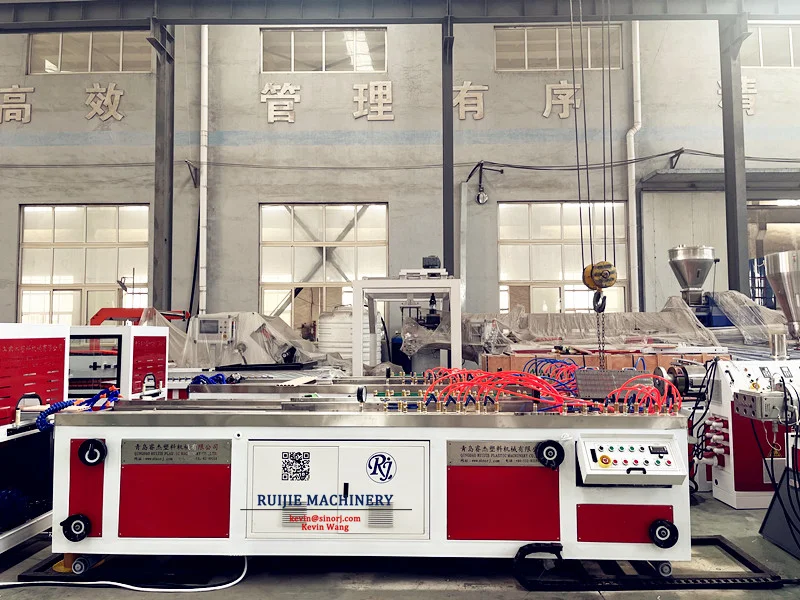

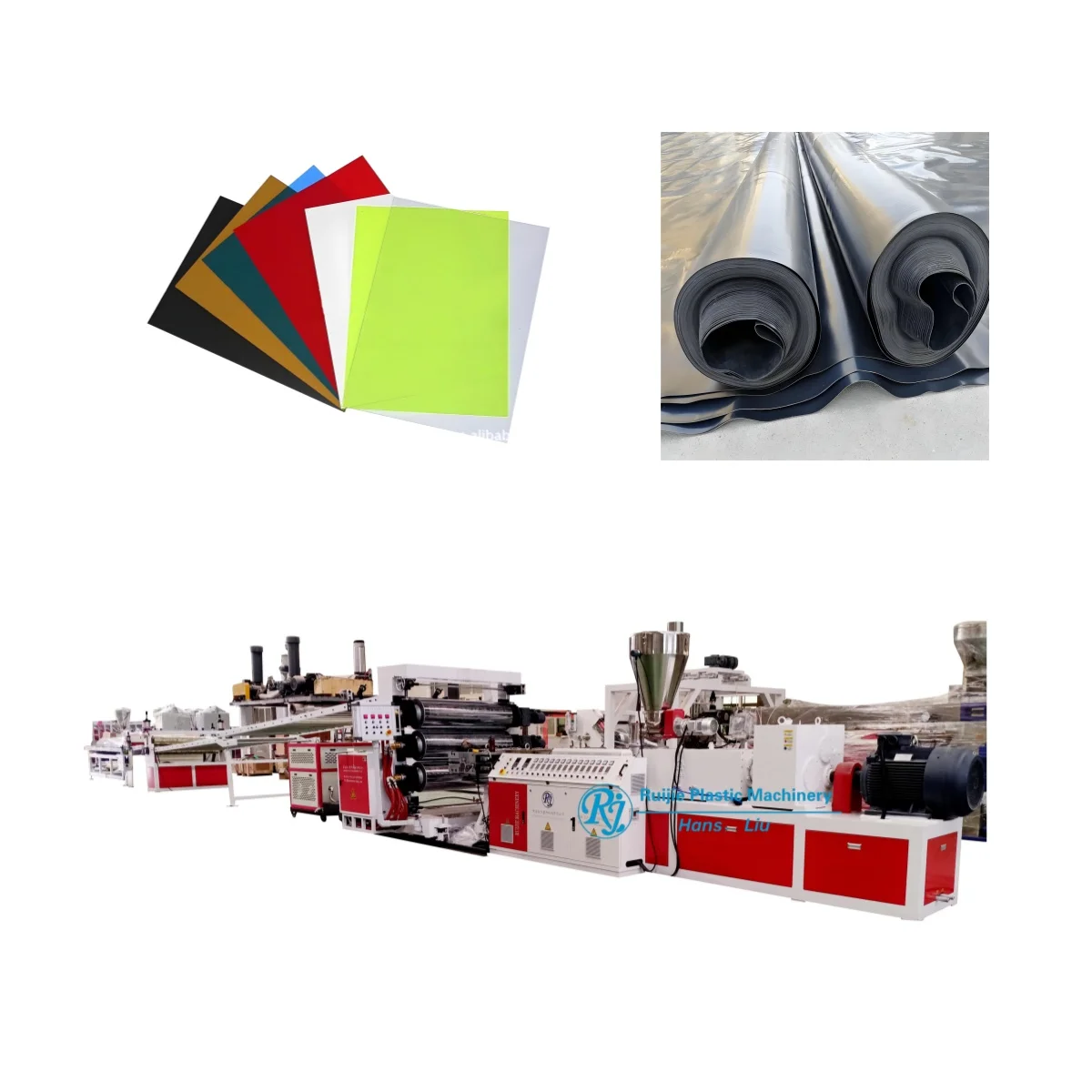

Machine Pictures

Pipe Application

Contact: +0086-15506393026(Wechat and Whatsapp)

Q:. Why I choose your company?

A: 1) We are one of the leading manufacturers of extruder machinery .

2) Our company has made extruder machine about 14 years with strong experience and advanced technology.

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance

4) We have Professional technical teams, and will supply 24 hours services.

Q: What should we prepare for Machine ?

A:You should prepare raw material, workshop, water line, electric line, compress air(if you need I can help you buy air compressor).

We would supply workshop layout drawing for you.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Qingdao city, Shandong province, you can fly to Qingdao AirPort. When you confirm the flight No. and time, please tell me then we will pick you up at Airport.

Q: If my machine can not work when I receive it, what will your factory do?

A: First of all, do not worry about the thing, we will test the machine before shipment. And if it happened, we will send our engineer to your factory to repair the machine.

Q: How can I believe your factory and machines.

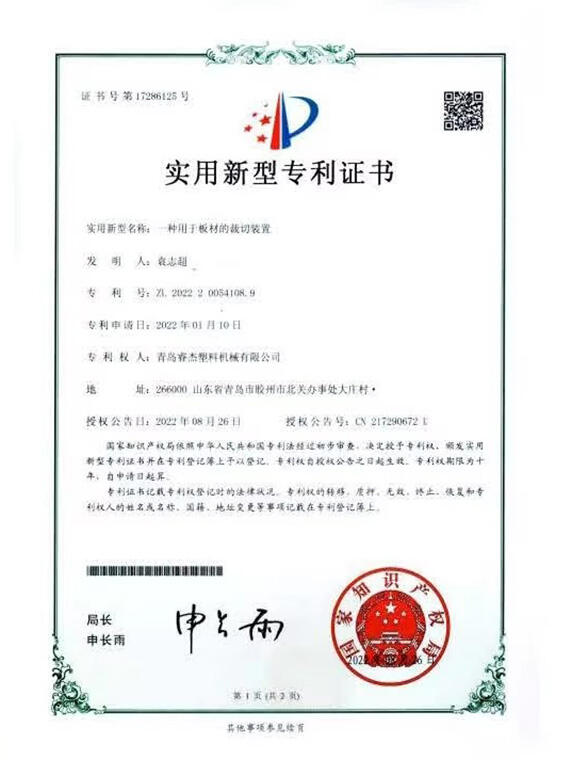

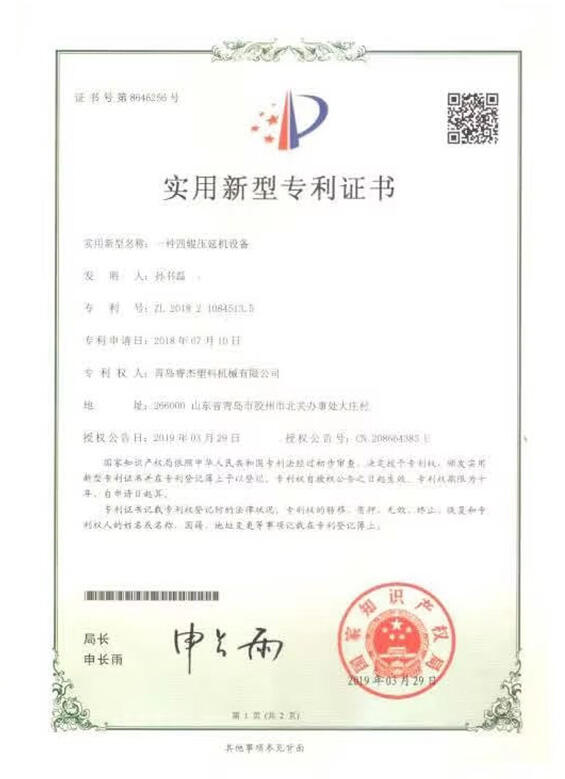

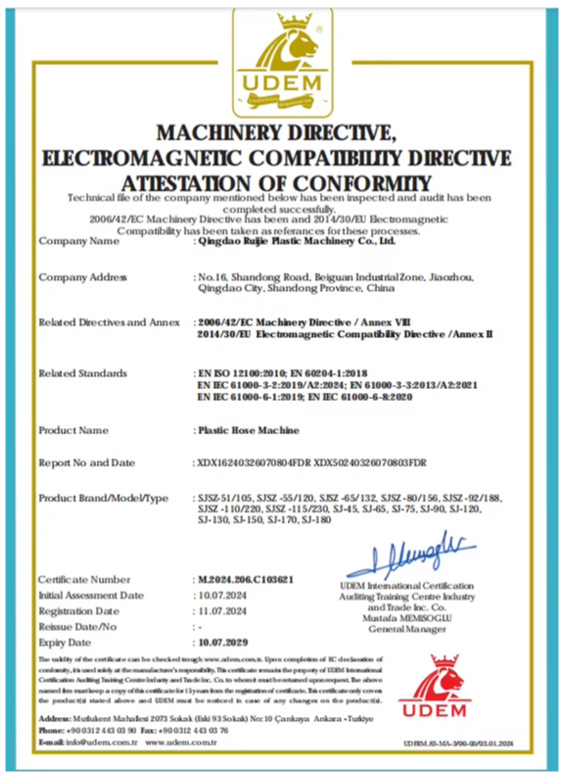

A: We have CE, ISO certificates. And we have customers all around the world, we can test the machine after it finished for your checking, if it do not reach your demands, we will change, or even give back your deposit.