All Categories

All Small Categories

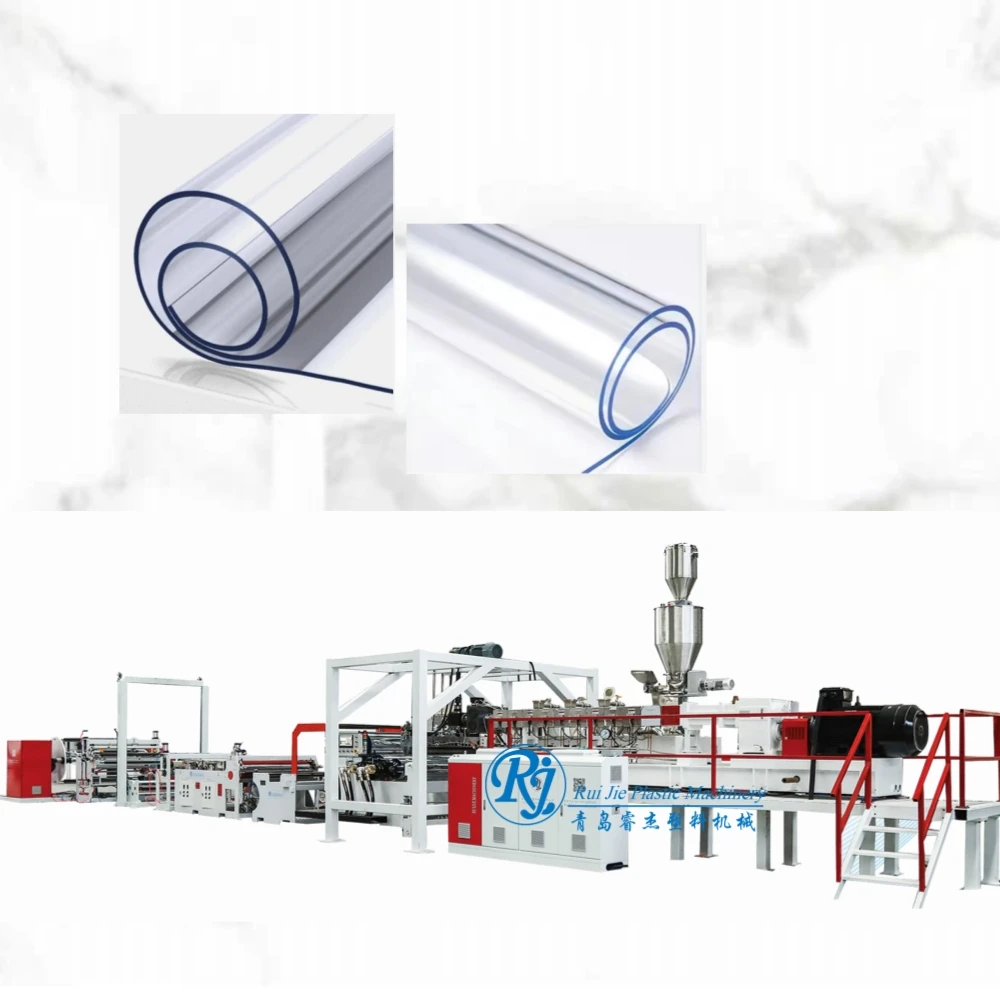

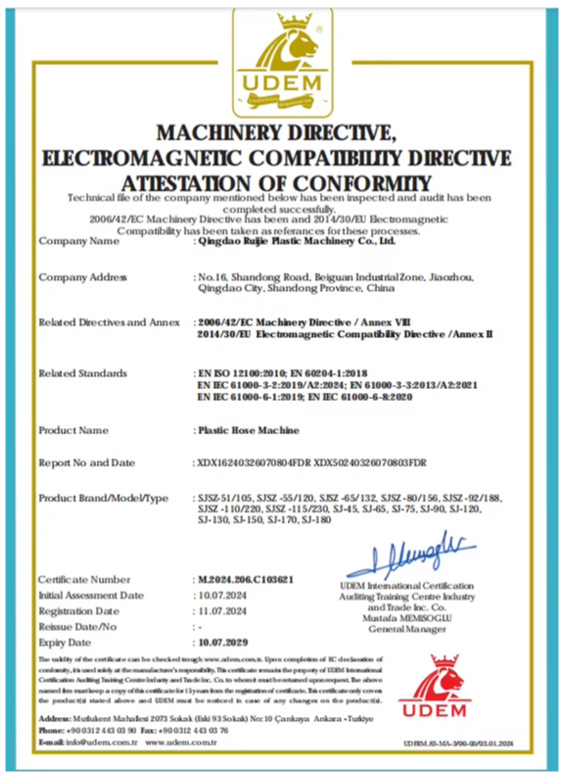

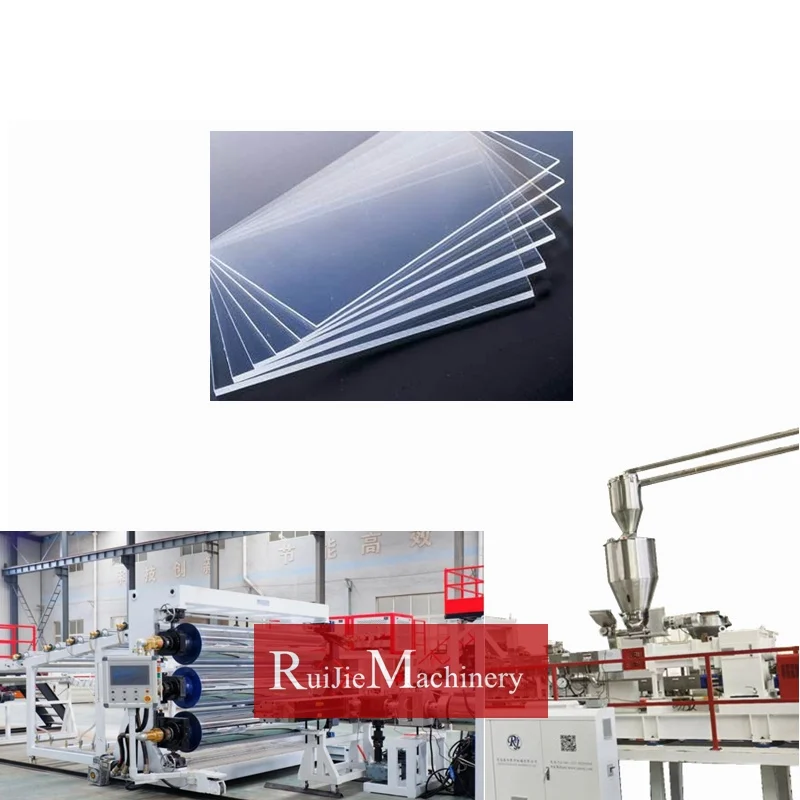

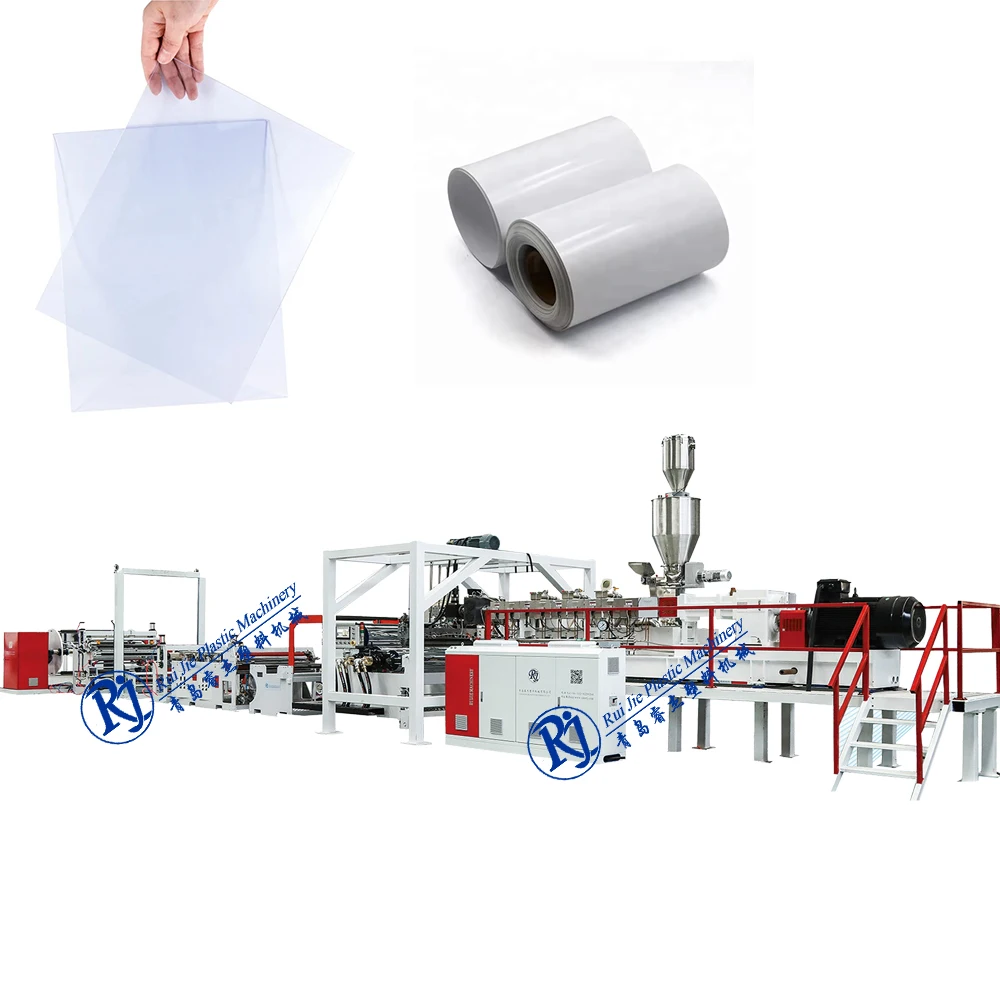

PVC PP PE WPC Wood Plastic Composite Wall Panel Profile Machine Extruder Production Line

- Description

NO. |

NAME |

1 |

SJSZ-55/120 EXTRUDER |

2 |

MOULD |

3 |

CALIBRATING TABLE |

4 |

HAUL OFF MACHINE |

5 |

CUTTER |

6 |

STACKER |

I. SJSZ-55/120 EXTRUDER

II. MOULD

III. CALIBRATING TABLE

IV. HUALING OFF MACHINE

V. CUTTER

VI. STACKER

Main Technical Parameters

1 |

Raw material |

PVC powder, calcium carbonate, stabilizer |

2 |

PVC CaCo3 Ratio |

1:1 |

3 |

Machine model |

SJSZ-55/120 |

4 |

Max useful width |

300mm |

5 |

Extrusion line with mixer |

23m(L)*4m(W)*5m(H) |

6 |

Total project Install power |

80kw (consumption: 50-60%) |

7 |

Products capacity |

3-4 tons/24hours |

Product Usage