All Categories

All Small Categories

Newly Manufactured PE HDPE PP PPR ABS Pipe Tube Making Machine Single-Screw Extruder Production Line New Motor PLC for PA

- Description

Description

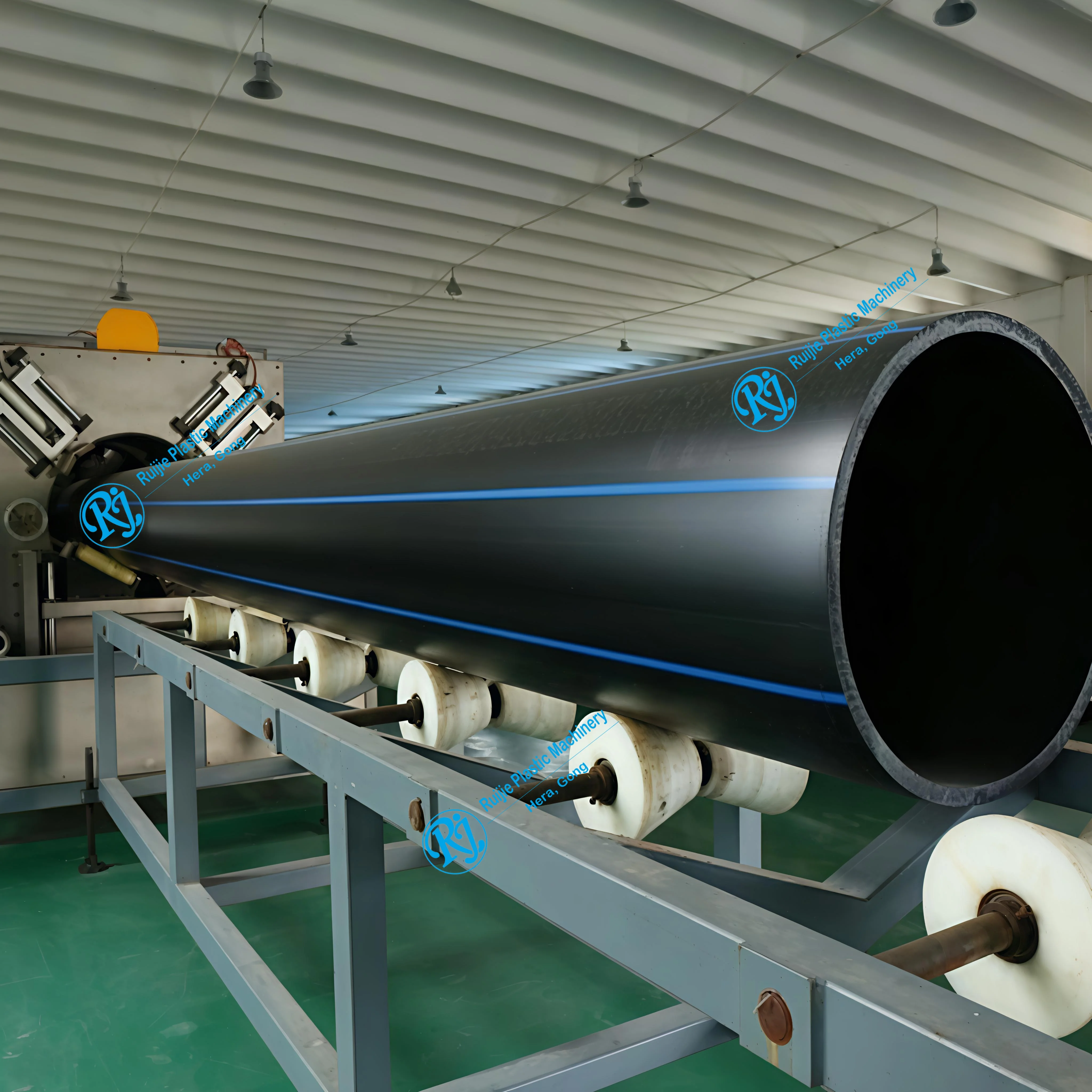

PE HDPE LDPE PPR Pipe Plastic Pipe Making Extruder Machine Production Line is primarily used in the manufacturing of HDPE pipes with diameters ranging from 12mm to 630mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two or three layer spiral mould for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.

Flow chart of PE pipe production line

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder→ color band extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker(or Winding machine)

Equipment list

1.Single screw extruder;

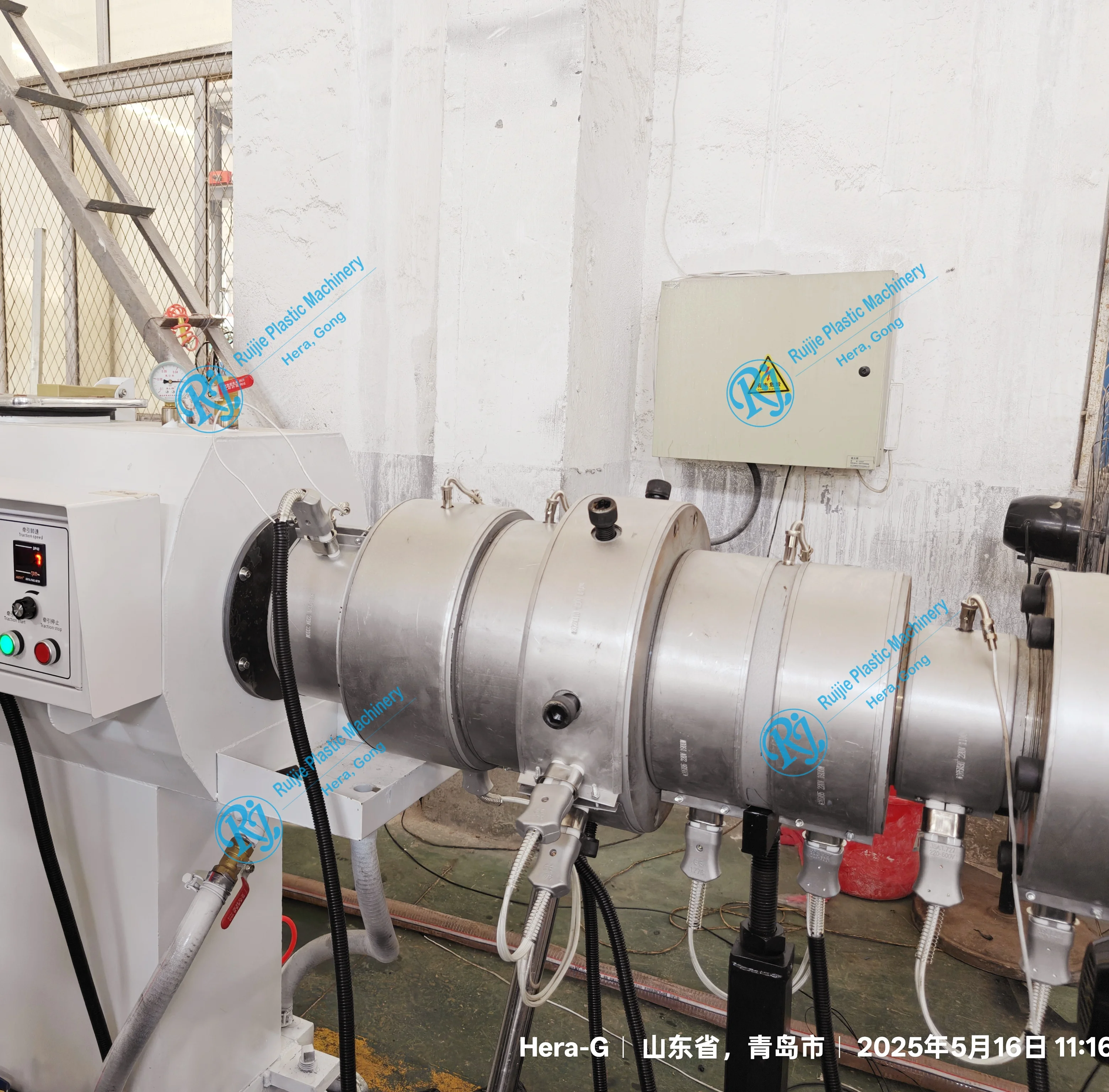

2. Mould (Die Head);

3.Vacuum calibrating and cooling tanks;

4. Water cooling tanks

5. Haul-off machine;

6. Winder or stacker.

Model

Model |

Pipe range(mm) |

Extruder |

Capacity(kg/h) |

Total install power(kw) |

PE-63 |

12-63 |

SJ65/30 |

120-180 |

110 |

PE-110 |

16-110 |

SJ65/30 |

150-200 |

130 |

PE-160 |

50-160 |

SJ75/30 |

150-220 |

150 |

PE-250 |

75-250 |

SJ75/30 |

250-350 |

280 |

PE-315 |

110-315 |

SJ90/30 |

280-350 |

350 |

PE-450 |

160-450 |

SJ90/30 |

350-450 |

400 |

PE-630 |

315-630 |

SJ120/30 |

550-850 |

550 |

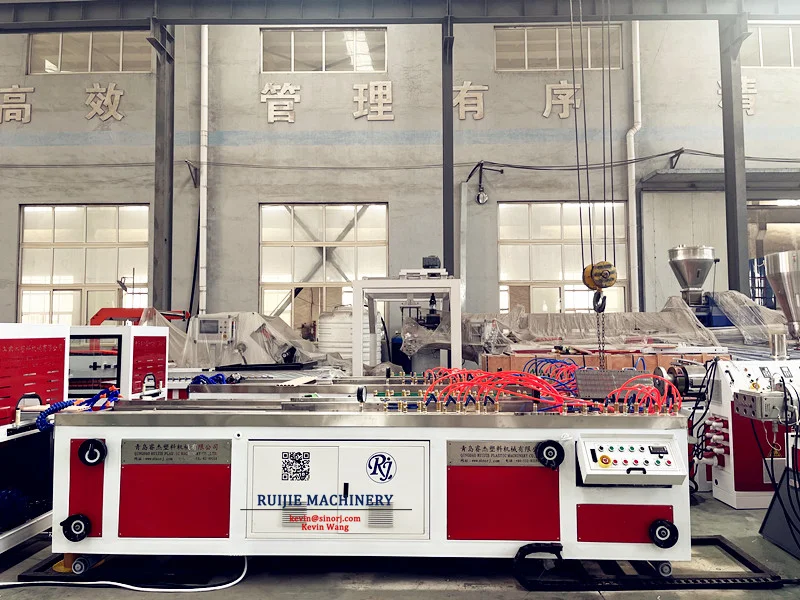

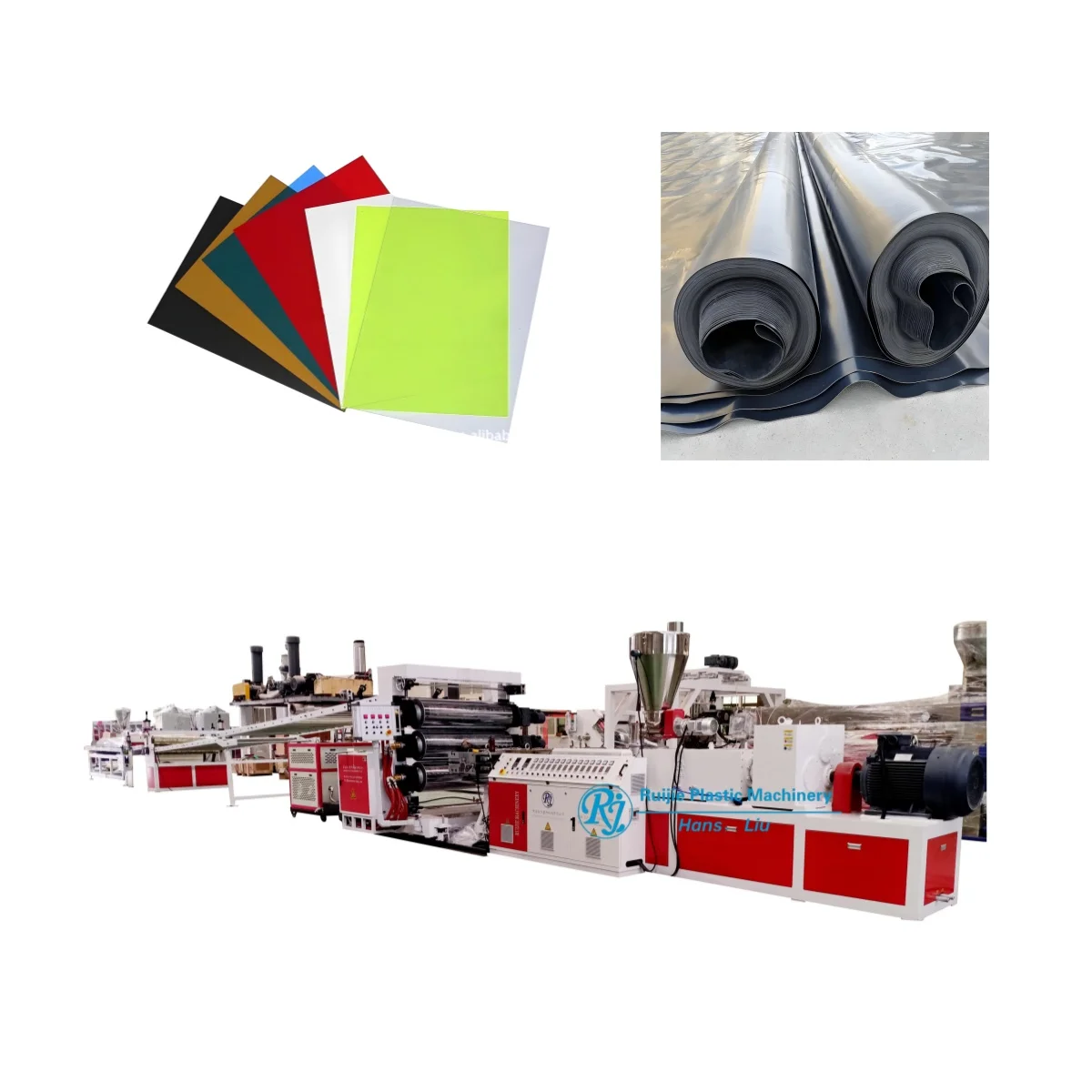

Machine Pictures

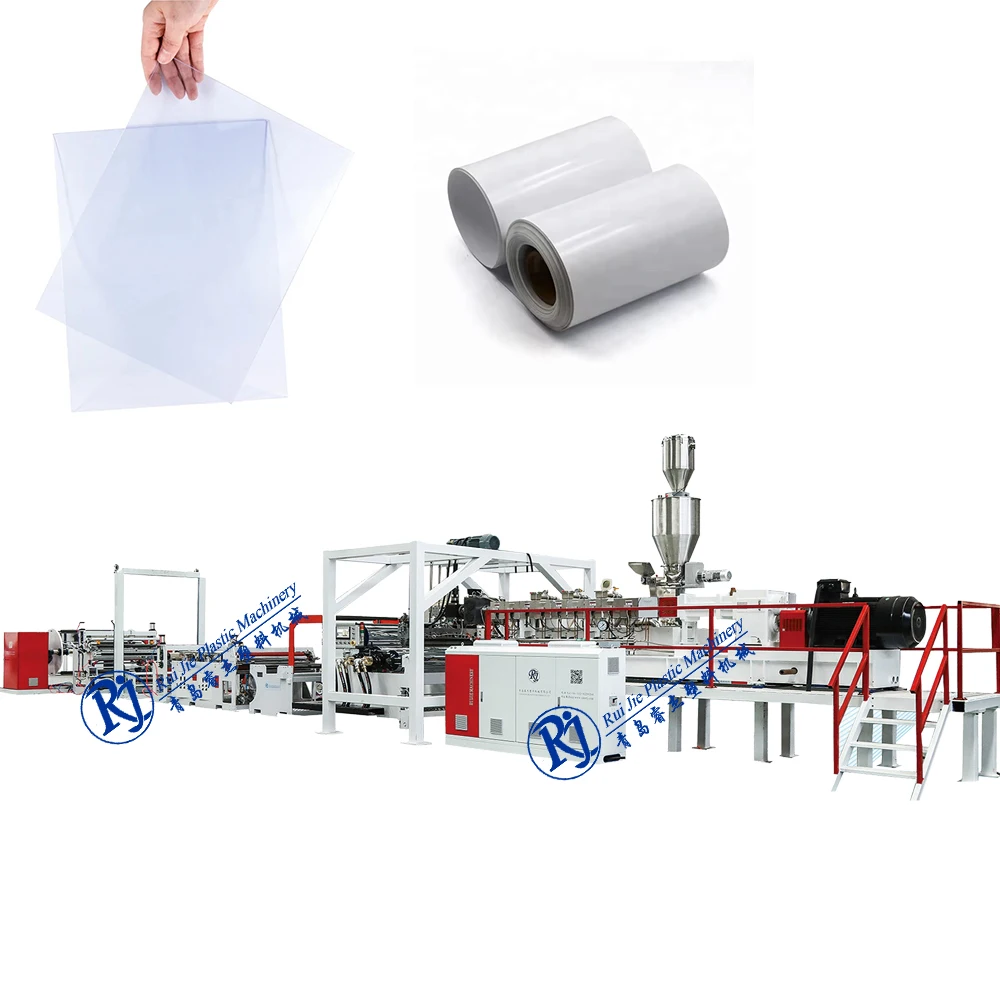

Product pictures

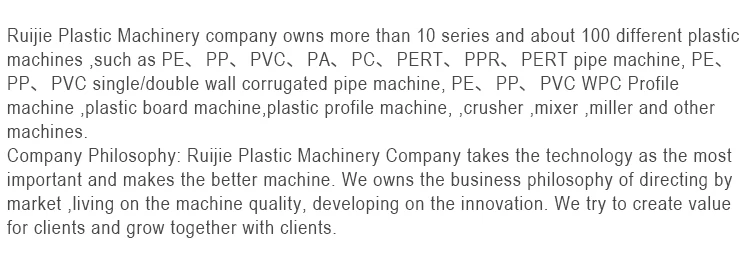

Q:. Why I choose your company?

A: 1) We are one of the leading manufacturers of extruder machinery .

2) Our company has made extruder machine about 14 years with strong experience and advanced technology.

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance

4) We have Professional technical teams, and will supply 24 hours services.

Q: What should we prepare for Machine ?

A:You should prepare raw material, workshop, water line, electric line, compress air(if you need I can help you buy air compressor).

We would supply workshop layout drawing for you.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Qingdao city, Shandong province, you can fly to Qingdao AirPort. When you confirm the flight No. and time, please tell me then we will pick you up at Airport.

Q: If my machine can not work when I receive it, what will your factory do?

A: First of all, do not worry about the thing, we will test the machine before shipment. And if it happened, we will send our engineer to your factory to repair the machine.

Q: How can I believe your factory and machines.

A: We have CE, ISO certificates. And we have customers all around the world, we can test the machine after it finished for your checking, if it do not reach your demands, we will change, or even give back your deposit.