All Categories

All Small Categories

PVC PIPE MAKING MACHINE PE PIPE PRODUCTION LINE PPR PERT EXTRUSION DRIP IRRIGATION PIPE MACHINERY PVC GAREN TUBEE EXTRUDER

- Description

Specification

| Type | Pipe size | Main extruder | max output |

| PE63 | 16-63 | SJ45/30 | 200 |

| PE250 | 75-250 | SJ75/33 | 400 |

| PE315 | 110-315 | SJ75/38 | 600 |

| PE450 | 160-450 | SJ90/35 | 1000 |

| PE800 | 450-800 | SJ120/33 | 1200 |

| PE1200 | 710-1200 | SJ150/33 | 1500 |

According to the various uses of plastic PE pipes, it is required to have both mechanical strength, heat resistance, cold resistance, transparency and other properties, and it is necessary to constantly have the emergence of new plastic pipes to replace traditional plastic pipes. PE pipe gradually from heavy to light, single function to multi-function development, co-extruded composite plastic three-layer PE pipe has become a new type of pipe. Because the various properties and functions of the co-extruded pipe can be designed according to needs, by selecting the appropriate matrix and reinforcement as well as the appropriate composition ratio and arrangement distribution, give full play to the performance advantages of the component materials, so as to obtain the comprehensive properties difficult to achieve by single materials such as metals, polymers, ceramics, such as high specific strength, high specific modulus, corrosion resistance, high temperature resistance and superconductivity, etc. Therefore, it has gradually become the development trend of plastic PE pipes in the future.

Advantages co-extrusion

1. Better product performance: Double-layer co-extrusion technology can extrude two different materials and compound them together, making full use of the advantages of two different materials to improve product performance.

2. The production process is simpler: compared with the traditional single-layer extrusion technical process, the double-layer co-extrusion technology production process is simpler and more energy saving.

4. Save resources: Double-layer co-extrusion technology can simplify the storage and processing of different kinds of materials, and reduce the waste of raw materials.

All in all, double-layer co-extrusion technology has become a core technology of modern plastic manufacturing and is widely used in all walks of life. With the continuous progress of science and technology, it is believed that double-layer co-extrusion technology will have a broader space for development

SJ65/33 Single screw Extruder→Mould →Vacuum cooling Tank-Spraying Cooling Tank→Two-claw Haul-off unit →Cutter with no-dust →Automatic Stacker

SJ150/33 Single-screw Extruder

Screw Diameter 150mm

Material 38CrMoAlA

Method AC motor

SJ45/25 Extruder for Mark Line

Mould(including heater and calibrator)

Method mouth die and core die are changeable

Form: spiral form

Vacuum Cooling Tank

Vacuum pump 11KW +****KW

Water pump 3KW

Haul-off unit

Haul-off method *********Caterpillar

Speed adjusting mode frequency-converting

Cutter with no-dust

Cutting motor 4KW

Motor speed 1*****rpm

stacker

Board overturning mode pneumatic

Automatic length-control Yes

Q: Why do I choose your company?

A: 1) We are one of the leading manufacturers of extruder machinery .

2) Our company has made extruder machine about 14 years with strong experience and advanced technology.

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance.

4) We have Professional technical teams, and will supply 24 hours services.

Q: What should we prepare for Machine ?

A:You should prepare raw material, workshop, water line, electric line, compress air(if you need I can help you buy air

compressor).We would supply workshop layout drawing for you.

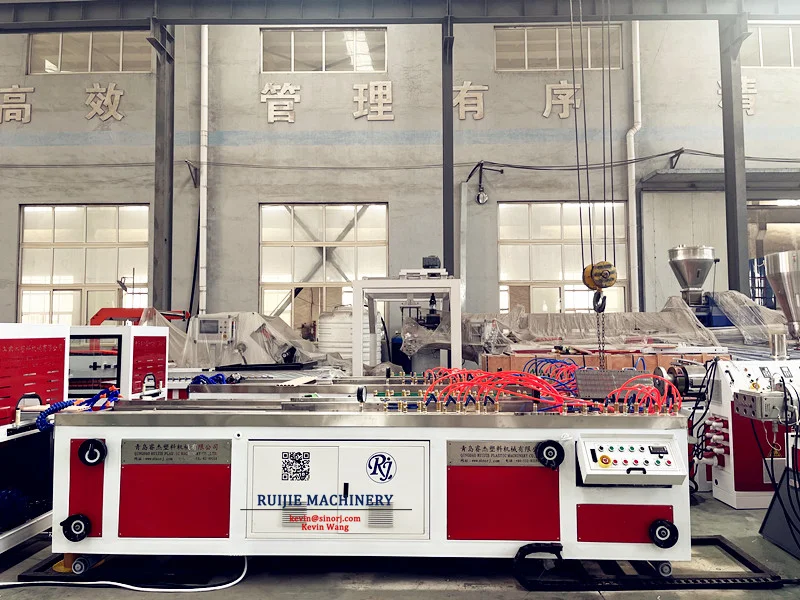

Q: Where is your factory located? How can I visit you?

A: Our factory is located in Qingdao city, Shandong province, you can fly to Qingdao AirPort. When you confirm the flight No. and time, please tell me then we will pick you up at Airport.

Q: If my machine can not work when I receive it, what will your factory do?

A: First of all, do not worry about the thing, we will test the machine before shipment. And if it happened, we will send our

engineer to your factory to repair the machine.

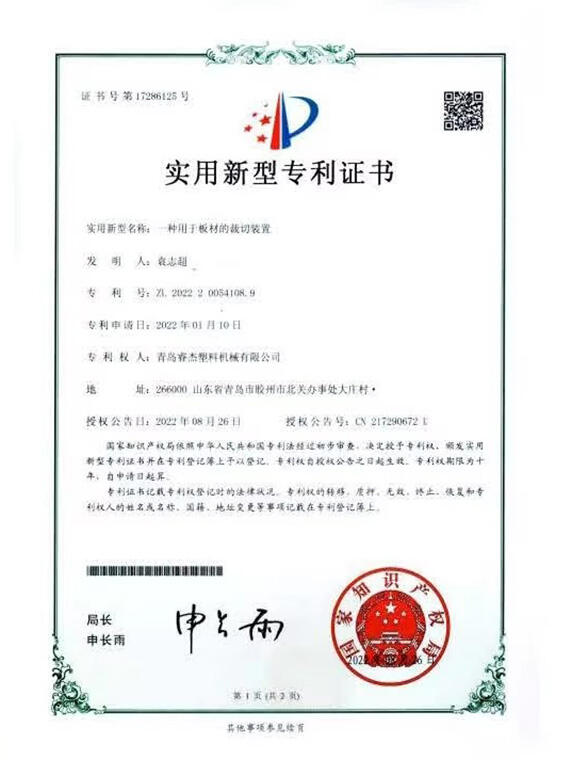

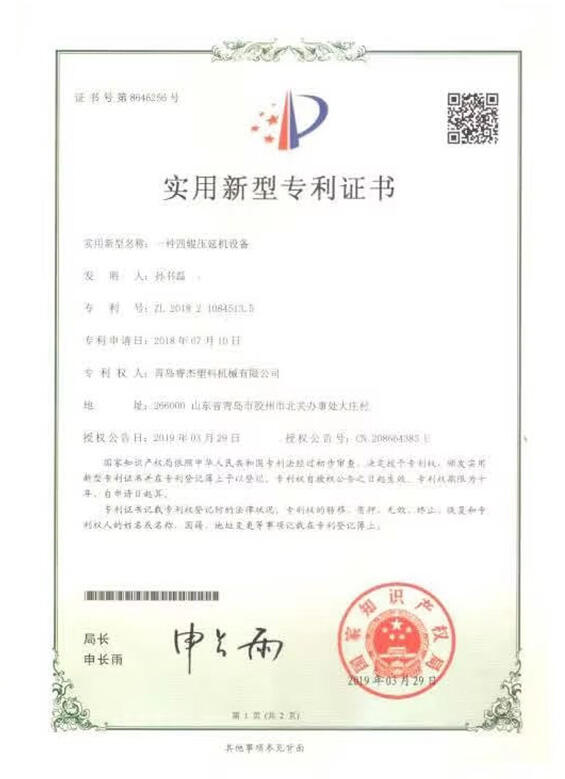

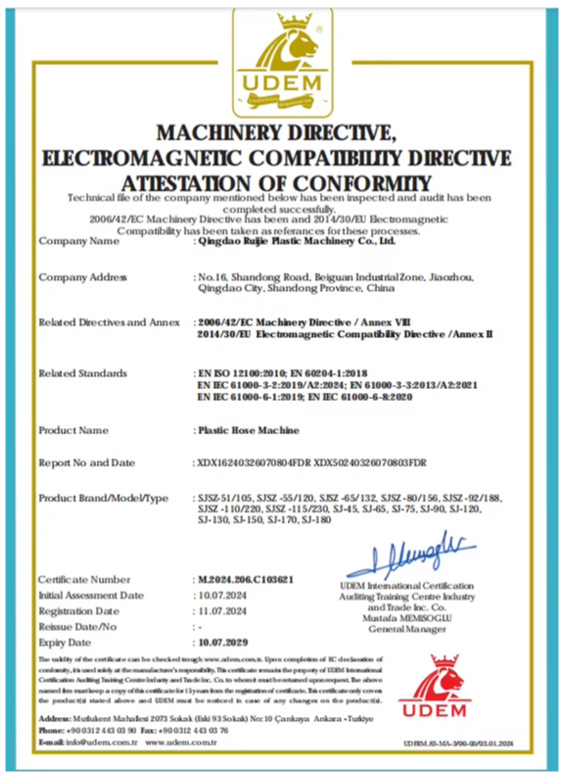

Q: How can I believe your factory and machines.

A: We have CE, ISO certificates. And we have customers all around the world, we can test the machine after it finished for your checking, if it do not reach your demands, we will change, or even give back your deposit.