All Categories

All Small Categories

PVC Twin-pipe Making Machine, UPVC Double Pipe Machine, PVC Dual Tube Extrusion Machinery

- Description

| Model | SJSZ51/105-65/132 |

| Pipe size | 16mm-630mm |

| Material | PVC Resin |

| Main motor | 18.5kw-110kw |

| Cutter | Fixed-length cutting machine |

| Stacker | 4/6 meters length |

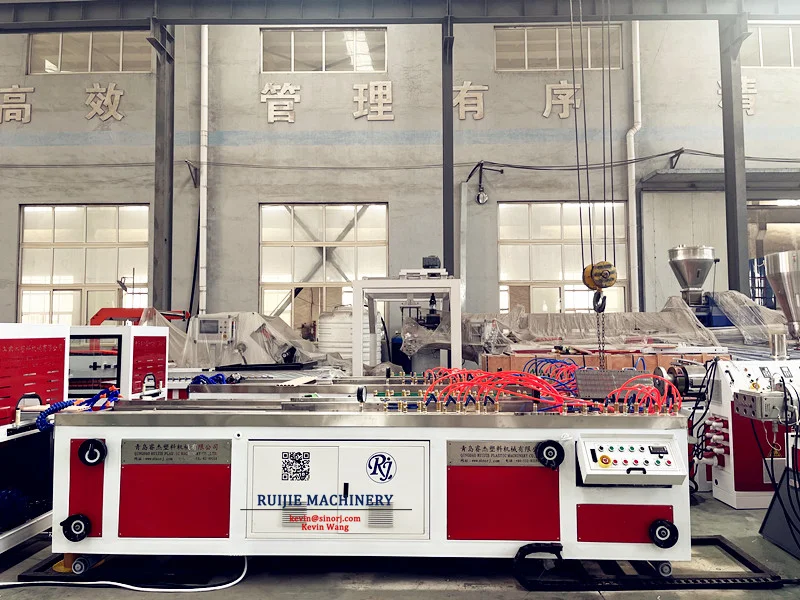

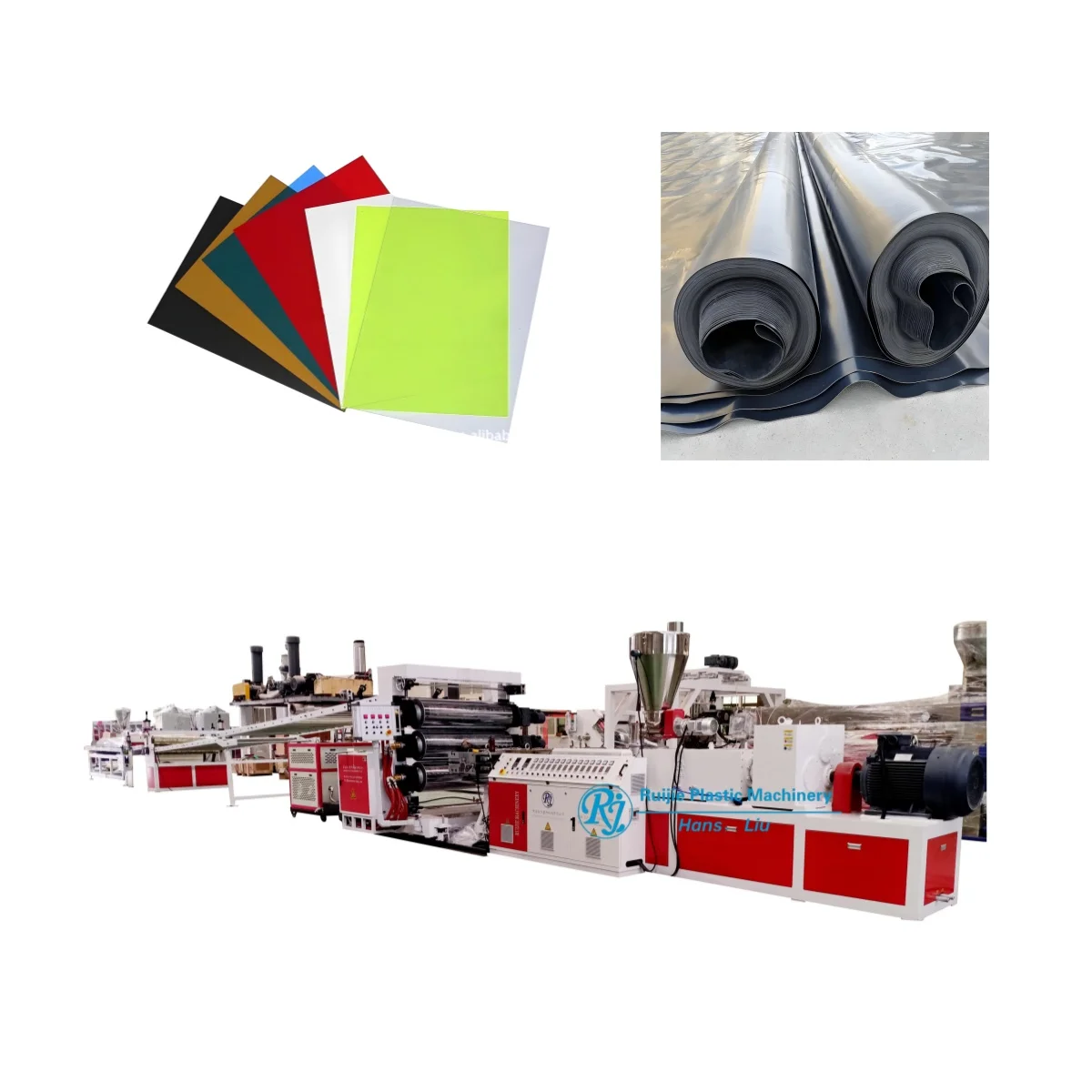

The Line Components

1. Double screws extruder(SJSZ51/105-92/188 )

2. Vacuum calibration tank

3. Haul off machine

4. Cutting machine

5. Auto stacker

6. The mixer machine, Crusher machine, and Miller machine are also optional for your real needs.

Extruder Advantages

1. Double screws feeder.

2. ABB/DELTA inverter, Siemens motors, Siemens contactors.

3. The PLC control system is optional.

4. High-quality gearbox, screws, and barrel.

5. Automatic feeder.

Product Usage